Featured Products

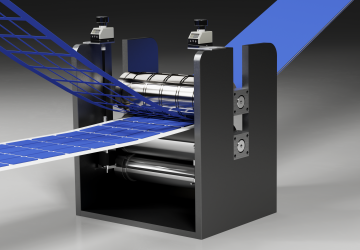

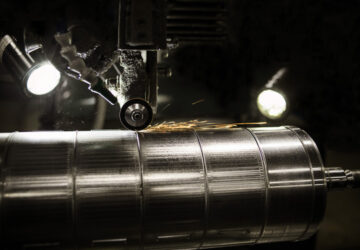

RotoAdjust Dual Adjustable Anvil

The new RotoAdjust offers state-of-the-art Industry 4.0 automation and data analytics to run better, faster, and smarter. Unlock tomorrow’s automation potential today.

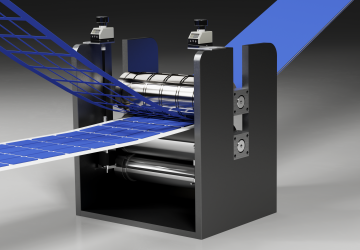

AccuAdjust Dual Adjustable Anvil

AccuAdjust solves liner variability issues and allows easy cutting of PET, Glassine, Kraft and more with a simple turn of a precision digital dial. Cut perfect labels and minimize material consumption no matter the liner material.

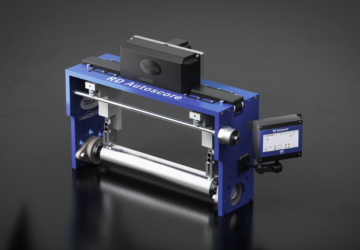

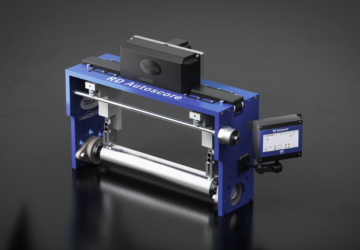

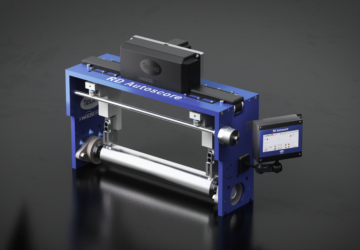

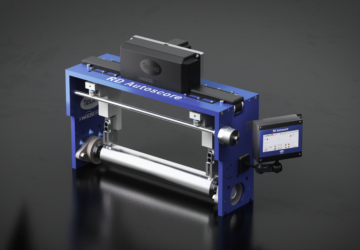

RD AutoScore

Keep operators safe and reduce setup time with the Tidland RD AutoScore system.

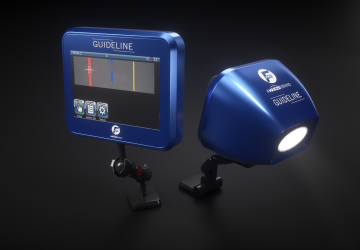

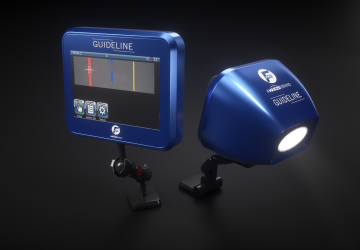

GuideLine Digital Line Guide Sensor

Detect lines, edges of lines, graphic patterns, and more where traditional line sensors don’t work at a competitive price point. The GuideLine is suitable for the most demanding line guide applications.

Maxcess News

Tidland Launches the Fully-Automated RD AutoScore

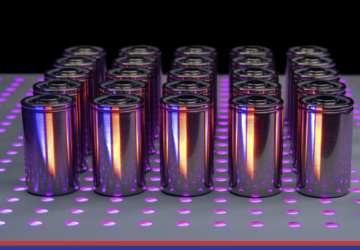

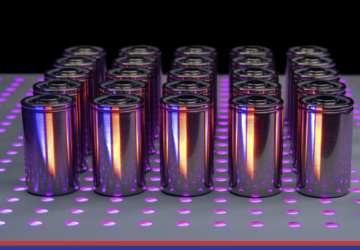

NEW Battery Solutions Brochure

Control Liner Variability TODAY with the new RotoAdjust

The solutions you need. When you need them. Anywhere in the world.

Maxcess saves you time and money by optimizing your peak output performance. We do this by leveraging the world’s best web handling brands, offering customized end-to-end web handling solutions.

We understand how winding equipment influences tension, tension influence guiding, and how guiding and tension together influence your ability to die-cut and slit the web effectively.

We are actively investing in Industry 4.0 solutions, creating safer automated systems that help customers run more sustainably while reducing dependency on skilled manual labor and minimizing human error. We’re Maxcess, we provide web handling solutions that helps you work better, faster and smarter.

Products

With our industry-leading brands, we’re the only partner in the industry that can provide this scope of quality end-to-end, unwind-to-rewind solutions.

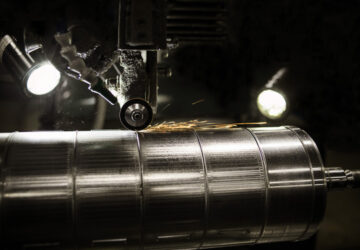

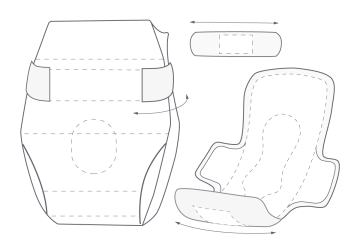

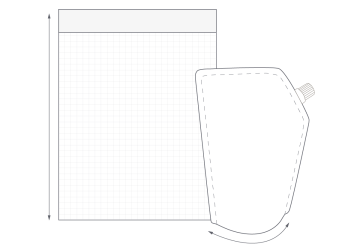

Rotary Dies

Customized precision cutting solutions for the efficient conversion of all web materials.

Web Guiding Solutions

Innovative web guiding and inspection systems providing solutions that have been minimizing waste and guaranteeing efficiency for nearly a century.

Tension Controls

Control systems, sensors and torque devices for every web tension control application.

Precision Rolls

From highly engineered solutions to rubber coverings, we manufacture the industry’s leading solution for precision rolls.

Industries

No matter your industry, Maxcess has a solution that fits. We’re ready to develop the right solutions for any partner.

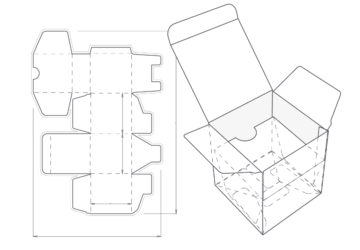

Packaging

An ever growing market, our packaging customers convert everything from tag and label, RFID, flexible packaging, food and beverage, corrugated, and pharmaceuticals. Find solutions for the packaging industry below.

Tag and Label

With a variety of flexible and solid die cutting tools and accessories, Maxcess is a favorite for those in the tag and label sector of the packaging industry.

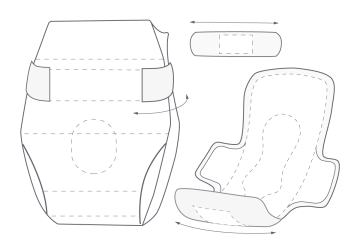

Nonwovens

Whatever your nonwoven application, we’ve got the right web handling processes and equipment to keep you moving forward.

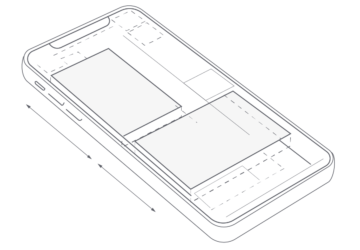

Battery

Keep your converting lines running more efficiently with our battery-specific industry solutions.

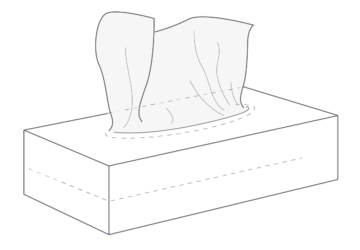

Towel and Tissue

Our multifunctional lines of tissue and towel covering options help you run better than ever.

Specialty Converting

When it comes to converting specialty materials, no one comes close to the breadth and depth of our solutions.

Metals

Convert even the toughest metals effectively and efficiently with Maxcess solutions.

Tire and Rubber

Tire and rubber manufacturers worldwide rely on the Maxcess line of web handling products and services to keep processes efficient and cost-effective.

Paper

Paper manufacturers throughout the world rely on the Maxcess line of web handling products and services to keep processes efficient and cost-effective.

We Support Our Customers Through

People

Delivering unparalleled support

Reliable Solutions

Working better together to create value

Innovation

Solving challenges from a "big picture" perspective

Your and your customers’ success relies on precisely engineered, timely-delivered converting line solutions. You need tools that help you maximize output – like integrated technology and professionals that understand every part of your converting line. When you partner with Maxcess, you get a deep commitment to next-generation solutions through our deep investments in R&D, decades of knowledge and customized technology, delivering solutions that fulfill your needs and maximize your success to run better, faster and smarter.

Maxcess Access e-Commerce

Get quick quotes, simple ordering and reordering, real-time delivery tracking, inventory management and more through MyMaxcess.com and MyRoto.com

Shop Online