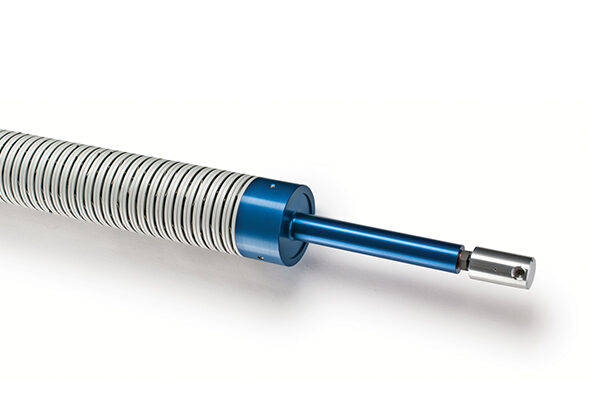

Eje diferencial D490

Elimina el polvo en el proceso de bobinado gracias al control de deslizamiento interno.

Asegura la mejor calidad de las bobinas gracias a los múltiples puntos de contacto en el diámetro interno del núcleo.

Brinda un control de tensión constante y predecible en múltiples materiales mediante el torque de fricción neumática contra el cartucho mecanizado.

Los ejes diferenciales D490 mantienen los rodillos rectos y nivelados. Los cartuchos intercambiables le permiten determinar cómo se engancha el eje al núcleo para que se adapte mejor al material y al núcleo que está utilizando. Puede escoger entre un diseño de resorte de alambre de calibre grueso (D490S) para núcleos de fibra o un diseño de 2 filas y 12 bolas activado mediante el torque (D490B) para núcleos de fibra o PVC.

El resultado es una mejora en la calidad de los rodillos terminados, una reducción del desperdicio, y una configuración rápida y sencilla, incluso en el caso de los materiales más sensibles. Dado que los ejes diferenciales D490 se fabrican en América del Norte, Europa y China, son fáciles de suministrar y reparar en todo el mundo. Todos los componentes cumplen con los más altos estándares de calidad de Tidland y son intercambiables independientemente del lugar donde se instale el eje.

*Comuníquese con el servicio de atención al cliente de Tidland para obtener más información sobre las opciones disponibles para su aplicación específica.

Eje diferencial D490

| Rango de DI del núcleo | 3 pulgadas, 3,005 - 3,040 pulgadas76,2 mm, 76,327 - 77,216 mm |

|---|

Eje diferencial D490 - Cartucho de resorte D490S

| Material del núcleo | Solo fibraSolo fibra |

|---|---|

| Ancho mínimo de corte* | 14 mm14 mm |

| Ø estándar | 3 pulgadas76,2 mm |

| Ancho del cartucho | 6, 10, 20 mm6, 10, 20 mm |

| Rango de tensión | 0,25 - 2 pli43,8 - 350,3 Nm |

je diferencial D490 - Cartucho de bolas D490B

| Material del núcleo | Fibra, PVCFibra, PVC |

|---|---|

| Ancho mínimo de corte* | 0,79 pulgadas20 mm |

| Ø estándar | 3 pulgadas76,2 mm |

| Ancho del cartucho | 9, 24 mm9, 24 mm |

| Rango de tensión | 0,50 - 4 pli 87,6 - 700,5 Nm87,6 - 700,5 Nm |

Manual de Usuario

Especificación de Producto

Solicitud de Cotización

- Alimentos y bebidas

- Batería

- Cartón

- Conversión de materiales de especialidad

- Empaque

- Empaque flexible

- Etiquetas y distintivos

- Materiales no tejidos

- Productos farmacéuticos

- Toallas y pañuelos

Productos relacionados

Interfaz del operador OI-TS del controlador D-MAX

User-friendly touchscreen operator interface allowing for easy and intuitive control of web guiding systems in industrial applications.

Portacuchillas electrónico de la serie Control:

Maximize operator safety, productivity and roll quality with Tidland’s Control Series. Features include an LED-backlit touchscreen interface, enhanced durability and available wireless operation.

Módulo de lectura digital de tensión DTR-65

The DTR-65 offers the ability to have a tension display on a machine panel with the option to also output a tension reference to a drive or PLC to remotely display or control tension.

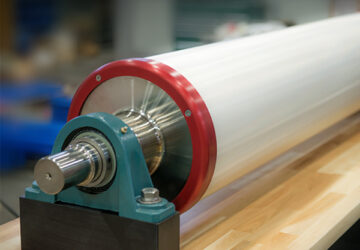

Rodillos de vacío Webex

A uniquely engineered internal vacuum system provides a strong, stable grip on a variety of materials, ensuring consistent and reliable web handling.