Product Subcategories

Spreader, Specialty Roll and Rubber Covering Solutions

Get precise, consistent results whether you’re working with metals, plastics, or other materials.

All Precision Rolls Products

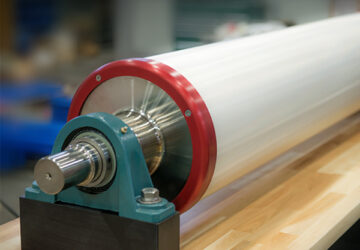

Mounts for Dead Shaft Idler Rolls

Mounts provide a stable, secure connection for idler rolls, ensuring consistent, reliable performance.

WINtrac and Anodized Coatings

A proprietary surface treatment improves traction and reduces friction, while anodized coatings offer increased corrosion resistance and a longer service life.

Electric HTR Roller

Achieve process temperatures quickly with minimal downtime while maintaining an even heat profile. With the ability to reach temperatures up to 850°F in just 1 hour, multiple heating zones for even heat distribution, and seamless integration options, the Electric HTR Roller offers a rapid and reliable solution for your production needs.

Webex Heat Transfer Rolls (Chill Rolls)

A uniquely engineered internal temperature management system allows for precise temperature control, ensuring consistent, reliable performance in heat transfer applications.

Vacuum Tension Rolls

A uniquely engineered internal vacuum system provides a strong, stable grip on a variety of materials, ensuring consistent and reliable web handling.

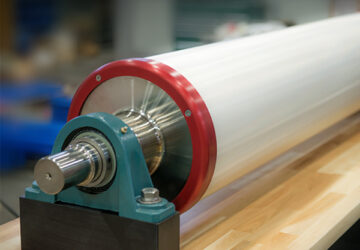

Webex Idler Rolls

We offer more than 400 standard configurations and numerous customizable options available for coating, plating, finish, groove patterns, shaft style, and environmental capabilities.

Webex Spreader Rolls

Expertly engineered internal design that ensures consistent, even spreading.

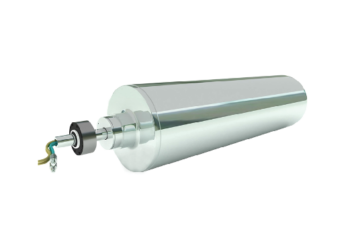

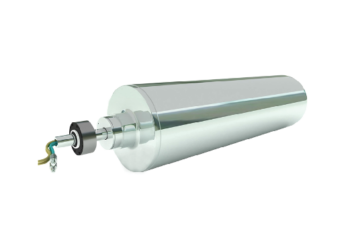

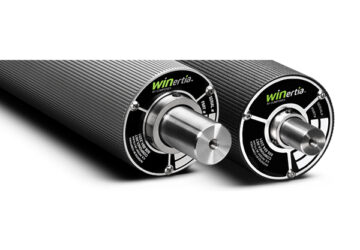

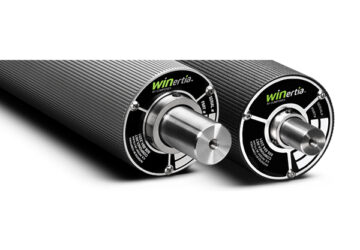

WINertia™ AV-Air Vent Aluminum Dead Shaft Idler

Featuring a special air vent design for consistent, reliable performance in demanding environments.

Componex WINertia ST- Smooth Tubing

Enjoy consistent, reliable performance, with a smooth, seamless finish.

WINertia™ Reverse Crown Spreader Roll

Easily remove wrinkles with this specially designed tapered dead shaft to achieve a greater surface speed at the ends of the roll.

Valley Roller Rubber Covered Roll Solutions

With more than 3,000 custom rubber compounds, you will dramatically improve your performance through our precise grinding tolerances that exceed industry standards, including the option for inspection for highly accurate measurements in applications requiring a near-perfect grind profile.

Webex Bowed Rolls

Bowed Rolls from Maxcess provide even tension and vibration-free operation for web separation and wrinkle elimination.

Specialty Rolls

Expertly designed, engineered, and custom built specialty rolls for various industries, with fast turnaround and decades of expertise. Contact us for your next project.