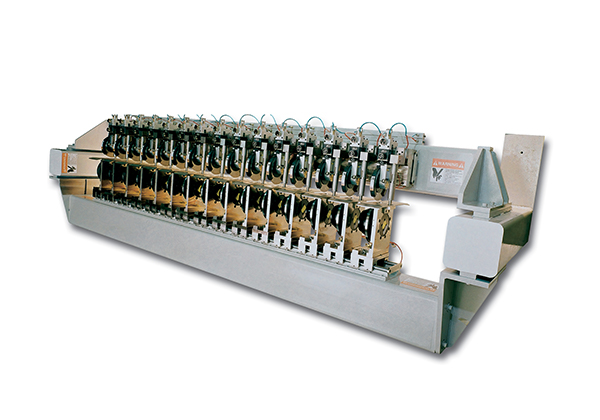

Hitchiker – Linked Slitting System

- Mill-Duty durability

- Increased slitter set-up accuracy and repeatability

- Faster order changes

- Ease of maintenance

- Easy retrofit

- Optional Equipment (may alter dimensions):

- Gear reducer (minimum slit widths are increased)

- Special motors based on speed requirements

- Custom web support platens

- Support frames

- Trim Chute

Hitchiker – Linked Slitting System Overview

Used in applications that involve multiple slits and need the best quality cut, Tidland’s durable and reliable Hitchiker Linked Slitting System drastically reduces web-out slitter setup time and improves slit quality. The Hitchiker allows repositioning of knifeholders and anvil rings simultaneously, maintaining the critical blade-to-anvil relationship. This affordable slitting system is available in two sizes, and is capable of handling smaller systems with 2-3 knives, as well as larger systems. The Hitchiker retrofits easily to most machines, accommodating virtually any web width and any number of slits.

Hitchiker - Linked Slitting System - Class II

| Carriages | Electroless nickel platedElectroless nickel plated |

|---|---|

| Knife Blade | 5.91 in150 mm |

| Anvil Blade | 7.48 in190 mm |

| Minimum Slit Width | 5.24 in133 mm |

| Speed Range (All Application)* | 114 - 1,463 mpm114 t- 1,463 mpm |

| Knifeholder Air (Filtered, Regulated Dry Air) | 4.1 - 5.2 bar4.1 - 5.2 bar |

| Carriage Brake Air (Filtered, Dry Air) | 5.5 - 6.9 bar5.5 - 6.9 bar |

| AC Motor Ratings | 0.11 - 0.96 kW0.11 - 0.96 kW |

| Power Requirements | 230 - 460 VAC 3-Phase230 - 460 VAC 3-Phase |

Hitchiker - Linked Slitting System - Class III

| CarriagesElectroless | Electroless nickel platedElectroless nickel plated |

|---|---|

| Knife Blade | 7.87 in200 mm |

| Anvil Blade | 9.84 in250 mm |

| Minimum Slit Width | 5.98 in152 mm |

| Speed Range (All Application) | 163 - 3,049 mpm163 - 3,049 mpm |

| Knifeholder Air (Filtered, Regulated Dry Air) | 4.1 to 5.2 bar4.1 to 5.2 bar |

| Carriage Brake Air (Filtered, Dry Air) | 5.5 - 6.9 bar5.5 - 6.9 bar |

| AC Motor Ratings | 0.11 - 0.96 kW |

| Power Requirements | 230 - 460 VAC 3-Phase0.11 - 0.96 kW |

Product Sheets

Featured Products

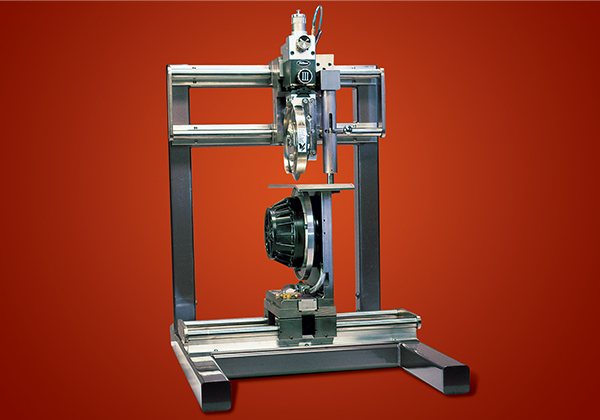

RotoAdjust Dual Adjustable Anvil

The new RotoAdjust offers state-of-the-art Industry 4.0 automation and data analytics to run better, faster, and smarter. Unlock tomorrow’s automation potential today.

AccuAdjust Dual Adjustable Anvil

AccuAdjust solves liner variability issues and allows easy cutting of PET, Glassine, Kraft and more with a simple turn of a precision digital dial. Cut perfect labels and minimize material consumption no matter the liner material.

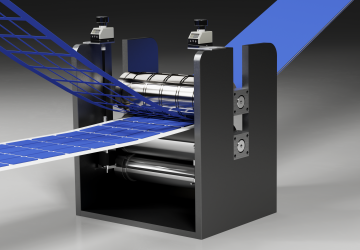

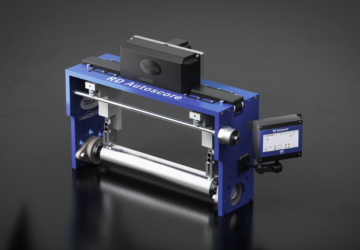

RD AutoScore

Keep operators safe and reduce setup time with the Tidland RD AutoScore system.

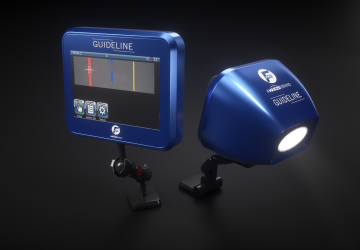

GuideLine Digital Line Guide Sensor

Detect lines, edges of lines, graphic patterns, and more where traditional line sensors don’t work at a competitive price point. The GuideLine is suitable for the most demanding line guide applications.