A more innovative, faster solution that lets Plitek focus on what matters

The Challenge: Thin Film, Costly Wrinkles

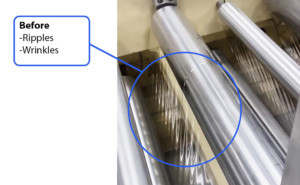

Plitek, a precision converter known for specializing in custom films and material processing with speed and versatility across a wide range of industries, encountered an issue in their sheet extrusion line when trial running a new material for a promising new customer.

Their speed and versatility were put to the test when tasked with this high-profile trial job. The material, a very expensive and thin, high-elongation polymer, began wrinkling during processing. These material properties coupled with the needed web-tension, made it very difficult to process while still achieving good roll uniformity.

Plitek strives for the highest level of quality in the converting services they offer and needed to find a solution that was quick and effective. Plitek’s engineering team had participated in the Maxcess roll and roll covering technology summit in November of 2024 and knew Maxcess would be a good partner in solving this challenge. Plitek’s engineering team worked closely with the Maxcess sales professional to identify a solution which was fast and effective. The Maxcess sales professional measured all of the roll positions and wrap angles while on site while really taking the time to understand the material challenge Plitek was looking to solve.

Why Traditional Fixes Fell Short

The industry-standard options were to either refurbish their existing spreader rolls with a rubber coat or change-out standard idler rolls with conventional spreader rolls, but that introduced its own challenges:

- 8-to-12-week lead time

- High cost of refurbishment

- Higher cost for new rolls

Their process line and their customer relationship couldn’t afford the delay.

The Maxcess Solution: WINertia AV Reverse Crown Spreader Roll

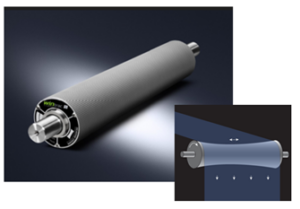

The Maxcess recommendation was clear: replace the under-performing spreader rolls and idler rolls with a Precision Rolls upgrade from Maxcess — specifically, a Componex WINertia™ AV Reverse Crown Spreader Roll.

How a Reverse Crown Spreads the Web

Unlike traditional spreader rolls, the WINertia™ AV Reverse Crown Spreader features a smaller diameter in the center and a larger diameter at the ends. This reverse taper creates greater surface speed at the roll edges—spreading the web outward to eliminate centerline slack and wrinkles.

Results in One Week

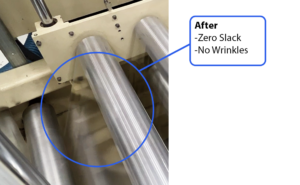

The lead time? Just one week. The cost? Less than half the price of the spreader roll refurbishment. Plitek installed the WINertia™ AV Reverse Crown Spreader Roll and immediately saw positive results.

“Maxcess’ solution is both affordable and fast. We would be foolish not to try it. These two factors made this a very easy decision.”

— Rob Larsen, Manager, Engineering and New Product Development, Plitek

Uniform Rolls, Output Gains & Cost Savings

- Wrinkles eliminated—clean rolls, zero slack.

- Roll length doubled with reduced stoppages and higher throughput

- Improved process control so operators could focus on dialing in critical parameters

- Faster trial completion met customer deadlines confidently

- Improved the overall material processing through the cooling, slitting, and winding stages

Today, Plitek has purchased multiple WINertia™ AV Reverse Crown Rolls for different processes and plans to continue expanding their use.

“When we can engineer out web handling problems on an extrusion line, it allows us to focus on the key areas. Processing thin, highly elastomeric extrusions is not an easy task. Maxcess once again has proved themselves to be a valuable partner in web handling solutions.”

— Rob Larsen, Manager, Engineering and New Product Development, Plitek

View the WINertia™ AV reverse crown roll specs

Key Takeaways for Converters: Performance Without Compromise

By challenging conventional thinking and embracing a purpose-built solution, Plitek resolved a complex material handling issue with speed and precision. The WINertia™ AV Reverse Crown Roller didn’t just fix a symptom; it enabled Plitek’s sheet extrusion line to confidently handle more challenging materials, without sacrificing speed, cost, or flexibility.

Talk to a Web-Handling Expert

Talk to an engineer about eliminating wrinkles →