Oak Brook, Illinois, June 12, 2023, Maxcess, a global leader in innovative products and services for web handling applications, today announced a breakthrough in its product lineup for the metals industry. Building upon its decades of leading ultrasonic, infrared, optical, capacitive, and inductive sensors, Maxcess introduces the new Fife ERW (Electromagnetic Radar Wave) Sensor. Through a five-year partnership with the Fraunhofer Institute for High Frequency Physics and Radar Techniques FHR, this innovative technology leverages radar waves to accurately detect the position of a metal strip through the insulation window of a furnace with temperatures exceeding 1000 °C.

“We are delighted to have partnered with the Fraunhofer FHR, a well-respected organization known for their commitment to innovation,” says Dr. Paul-Philipp Zänker, Research and Development Manager for Maxcess Europe. “The introduction of radar technology marks a significant milestone in our company’s history, and we are excited to introduce it to the market.”

Unlike existing radar sensors, the Fife ERW Sensor from Maxcess provides unparalleled accuracy, being up to 6 times more precise than the competition. This achievement significantly reduces waste and scrap, helping industries optimize their processes to achieve greater efficiency while providing a more sustainable solution.

To experience the capabilities of the Fife ERW Sensor firsthand, visit Maxcess’ booth (4D 16) at the METEC tradeshow in Düsseldorf in June 12-16, 2023, where live demonstrations will be available.

About the Fife ERW Sensor:

This new radar sensor is used for treatment lines for non-contact detection of the center position of metallic strips. lt is an alternative to the well-known capacitive or inductive strip center sensors used today in continuous process furnaces. The conversion from existing sensor technology to the new radar sensor is fast and easy.

Its main benefits are a completely maintenance free system, enhanced operational reliability, high precision, easy installation, and an insensitivity to pollutions of all kinds.

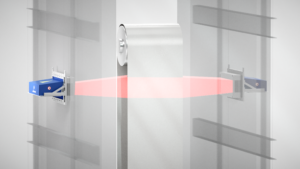

A system consists of two radar measurement devices on each side of the furnace detecting the position of the metal strip through the thermal insulation from the outside. The transmitting antenna emits electromagnetic radar waves, through the furnace window onto the side of the metal strip. The reflections from the side of the strip are picked up by the receiver antennas. By evaluating the time taken for the radar wave to return, the position of the metal strip is determined. The strip’s center position is calculated from both distance values and controls in real time the position of the strip.

About Maxcess:

Maxcess helps its customers maximize productivity through innovative and sustainable products and services worldwide. By combining more than 400 years of global service and support across the storied product brands of RotoMetrics, Fife, Tidland, MAGPOWR, Webex, Valley Roller and Componex, Maxcess offers an unrivaled network of application experts and end-to-end web handling solutions to help you work better, faster and smarter. Visit them online at www.maxcess.com

Press contact Maxcess:

Sandra Golembiewski

Marketing & Communication Manager EMEA

Fife-Tidland GmbH

Max-Planck-Strasse 8

65779 Kelkheim

Tel +49 6195 7002 425