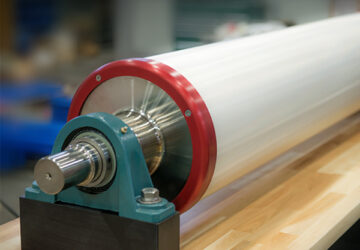

Ejes tipo lámina para fábricas

Ideal para aplicaciones pesadas como procesamiento de metales y carretes de papel.

El estilo tipo lámina brinda una mayor superficie de bobinado y es óptimo para eliminar la deformación del núcleo.

Estructura duradera diseñada para resistir el maltrato y la abrasión.

El eje tipo lámina para fábricas de Tidland está diseñado para núcleos con un diámetro interno (DI) de entre 178 mm y 610 mm (7 in y 24 in) para trabajos pesados, así como para operaciones sin núcleos. Este es el eje tipo lámina de mayor diámetro disponible y es excelente para los trabajos más duros como enrollar metal y láminas. También puede utilizarse como bobina de carrete para carretes de papel y máquinas de papel grandes. Estos ejes tipo lámina proporcionan un control exitoso del rodillo y eliminan la deformación del núcleo de pared delgada. Los ejes de la serie 750 tienen una sujeción de expansión radial de 360 grados a lo largo de toda la superficie de la lámina, proporcionan más superficie de bobinado y permiten el bobinado de rodillos individuales o múltiples, con o sin núcleos.

*Capacidad de torque aproximada

Capacidades de torque de los ejes para fábricas por tamaño nominal del núcleo*

| Tamaño nominal del núcleo | 8 pulgadas203,2 mm |

|---|---|

| Núcleo de fibra | 461 lb-in461 lb-in |

| Núcleo de acero | 304 lb-in304 lb-in |

| Tamaño nominal del núcleo | 10 pulgadas254 mm |

| Núcleo de fibra | 671 lb-in671 lb-in |

| Núcleo de acero | 443 lb-in443 lb-in |

| Tamaño nominal del núcleo | 12 pulgadas304,8 mm |

| Núcleo de fibra | 1107 lb-in1107 lb-in |

| Núcleo de acero | 731 lb-in731 lb-in |

| Tamaño nominal del núcleo | 16 pulgadas406,4 mm |

| Núcleo de fibra | 1476 lb-in1476 lb-in |

| Núcleo de acero | 974 lb-in974 lb-in |

| Tamaño nominal del núcleo | 24 pulgadas609,6 mm |

| Núcleo de fibra | 2952 lb-in2952 lb-in |

| Núcleo de acero | 1948 lb-in1948 lb-in |

Manual de Usuario

- Alimentos y bebidas

- Cartón

- Conversión de materiales de especialidad

- Empaque

- Empaque flexible

- Etiquetas y distintivos

- Productos farmacéuticos

Productos relacionados

Kantiroller

Bobinas de carrete de Tidland

The Series 860 is a heavy-duty air shaft designed for maximum reliability and performance in demanding mill environments, reducing the cost and storage of expensive reel spool mandrels. The ergonomic design also provides increased safety, eliminating the need for locking collars or wrenches.

Celdas de carga GTS

MAGPOWR’s GTS Global Load Cell ensures stability and accuracy, allowing tension to be precisely measured and controlled on a roll.

Rodillos de vacío Webex

A uniquely engineered internal vacuum system provides a strong, stable grip on a variety of materials, ensuring consistent and reliable web handling.