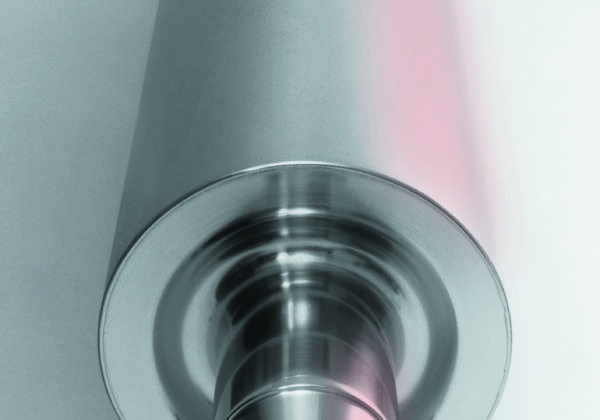

WEBEX Steel Live Shaft Idler Rolls

Trust WEBEX steel live shaft idlers for the strength and consistency your toughest web handling applications demand. These heavy-duty idler rollers support high loads, resist contamination, and maintain precision even in extreme environments.

Key Benefits:

- 1026 carbon steel tubing and 1018 carbon steel journals

- Available in 3″–6″ diameters and up to 120″ face lengths

- Bearings mounted externally to avoid contamination

- Withstands elevated temperatures and harsh conditions

- Custom shaft, groove, and coating options available

The WEBEX Steel Live Shaft Idler Rolls by Maxcess is engineered for the heaviest demands of web handling—combining high-load capacity, thermal durability, and contamination resistance in one robust solution. Constructed from 1026 carbon steel tubing with 1018 carbon steel journals, this steel live shaft idler performs reliably under extreme conditions like solvent-rich ovens, nip stations, or dusty converting lines.

Consistent Web Tension & Reduced Vibration

Available in nominal diameters of 3", 4", 5", and 6" with face lengths up to 120", this steel live shaft roll offers strength where it matters most. Bearings are mounted externally to avoid contamination and extend life, making it a trusted choice in harsh, high-temperature environments. Each heavy-duty idler roller is precision-machined to strict tolerances and can be customized with coatings and surface modifications for specific application needs.

Long-Lasting Operation

Withstand extreme temperatures, heavy nip pressure, and chemical exposure—ideal for lines where dead shaft rollers break down.

Optimized Shaft Configuration

Journals are made from 1018 carbon steel and support self-aligning pillow block or flange bearings for added load support and alignment flexibility.

Custom Widths

Standard sizes available up to 120 inches in face length, with custom width and surface options available on request.

Available Coatings

- Electroless Nickel

- Rubber Covering

- High Release Tungsten Carbide (Plasma)

- Chrome Plating

Machined Surface Options

- Reverse Taper, Chevron Groove, Spiral “V” Groove

- Matte Finish, Diamond Knurl, Herringbone Groove, Micro Groove

Common Applications

- High-load converting systems

- Ovens and solvent-rich environments

- Web handling zones with excessive dust, heat, or chemicals

- Laminating, printing, and industrial drying lines

Request A Quote

Upgrade your web handling system with WEBEX steel live shaft idlers. Contact Maxcess today to speak with an applications engineer or request a quote.

A-200-075

| Nominal Diameter | 2.050.8 mm |

|---|---|

| Wall Thickness | 1/4 in6.35 mm |

| Balance Speed | 1,000 FPM (dynamically balanced) |

| Face Straightness & Runout | Within the greater of 0.002 in or 0.0005 in/foot of face length |

| Max Face Length | 50 in1270 mm |

| Weight Formula | 1.00 + (0.11 × Face Length in inches) |

| Available Shaft Diameters | 0.75 in19.05 mm |

2.5 x 2

| Finished Roll Diameter | 2.5" -2.36"59.94-63.5mm |

|---|---|

| Total Indicator Run Out (TIR) | 0.0005 Per Foot (0.002 Min) Ra |

| Surface Finish | 16, 32, 64, or 125 ra16, 32, 64, or 125 ra |

| Bore Available | Ring Clip Bore (Bearing Protrusion Available) |

| Bearing Sizes Available | 1.0 in, 1.25 in, 25 mm1.0 in, 1.25 in, 25 mm |

| Bearing Type | Self Adjusting, ER, Free Spin |

| Balanced to Spec G6.3 | 2000 FPM (as specified) |

| Shaft Diameter Tolerance | -0.0005 / -0.0015 (Ex: 1.0" = 0.9995/ 0.9985) |

| End Cap | No end cap |

| Approximate weight | 0.1500 Pounds Per Inch (without shaft or bearings) |

3.1 x 1.5

| Finished Roll Diameter (Wide Web) | 3.040 / 2.985 in77.21/75.84 mm |

|---|---|

| Finished Roll Diameter (Narrow Web) | 3.005 / 2.985 in76.32/75.82 mm |

| Total Indicator Run Out (TIR) | 0.0005 Per Foot (0.002 Min) Ra |

| Surface Finish | 16, 32, 64, or 125 ra0.4, 0.8, 1.6, 3.2 µm |

| Bore Available | WINlock Bore |

| Bearing Sizes Available | 0.75 in19.05 mm Self Adjusting, ER, Free Spin |

| Balanced to Spec G6.3 | 2000 FPM (or as specified) |

| Shaft Diameter Tolerance | -0.0005 / -0.0015 (Ex: 1.0" = 0.9995/ 0.9985) |

| End Cap | Standard |

| Approximate Weight | 0.150 Pounds Per Inch (without shaft or bearings) |

3 x 2

| Finished Roll Diameter | 3.140 / 3.050 in79.75/77.47 mm |

|---|---|

| Total Indicator Run Out (TIR) | 0.0005 Per Foot (0.002 Min) Ra |

| Surface Finish | 16, 32, 64, or 125 ra16, 32, 64, or 125 ra |

| Bore Available | WINlock Bore |

| Bearing Sizes Available | 1.0 in, 1.25 in, 25 mm1.0 in, 1.25 in, 25 mm |

| Bearing Type | Self Adjusting, ER, Free Spin |

| Balanced to Spec G6.3 | 2000 FPM (or as specified) |

| Shaft Diameter Tolerance | -0.0005 / -0.0015 (Ex: 1.0" = 0.9995/ 0.9985) |

| End Cap | No end cap |

| Approximate Weight | 0.209 Pounds per Inch (without shaft and bearings) |

3.5 x 2

| Finished Roll Diameter (Wide Web) | 3.570 / 3.470 in |

|---|---|

| Finished Roll Diameter (Narrow Web) | 3.470 / 3.450 in90.68/88.14 mm |

| Total Indicator Run Out (TIR) | 0.0005 Per Foot (0.002 Min) Ra |

| Surface Finish | 16, 32, 64, or 125 ra 0.4, 0.8, 1.6 or 3.2 µm |

| Bore Available | WINlock Bore |

| Bearing Sizes Available | 1.0 in, 1.25 in, 25 mm1.0 in, 1.25 in, 25 mm |

| Bearing Type | Self Adjusting, ER, Free Spin |

| Balanced to Spec G6.3 | 2000 FPM (or as specified) |

| Shaft Diameter Tolerance | -0.0005 / -0.0015 (Ex: 1.0" = 0.9995/ 0.9985) |

| End Cap | Standard |

| Approximate Weight | .284 Pounds Per Inch (without shaft or bearings) |

4 x 2

| Finished Roll Diameter (Wide Web) | 4.100 / 3.975 in104.14/100.96 mm |

|---|---|

| Finished Roll Diameter (Narrow Web) | 3.955 / 3.935 in100.45/100.038 mm |

| Total Indicator Run Out (TIR) | 0.0005 Per Foot (0.002 Min) Ra |

| Surface Finish | 16, 32, 64, or 125 ra16, 32, 64, or 125 ra |

| Bore Available | WINlock Bore |

| Bearing Sizes Available | 1.0 in, 1.25 in, 25 mm1.0 in, 1.25 in, 25 mm |

| Bearing Type | Self Adjusting, ER, Free Spin |

| Balanced to Spec G6.3 | 2000 FPM (or as specified) |

| Shaft Diameter Tolerance | -0.0005 / -0.0015 (Ex: 1.0" = 0.9995 / 0.9985) |

| End Cap | Standard |

| Approximate Weight | .346 Pounds Per Inch (without shaft and bearings) |

4 x 3

| Finished Roll Diameter (Wide Web) | 4.220 / 4.100 in107.188 /104.14 mm |

|---|---|

| Finished Roll Diameter (Narrow Web) | 4.100 / 4.080 in104.14/103.63 mm |

| Total Indicator Run Out (TIR) | .0005 Per Foot (0.002 Min) Ra |

| Surface Finish | 16, 32, 64, or 125 ra16, 32, 64, or 125 ra |

| Bore Available | WINlock Bore |

| Bearing Sizes Available | 1.5 in, 2.0 in, or 40 mm1.5 in, 2.0 in, or 40 mm |

| Bearing Type | Self Adjusting, ER, Free Spin |

| Balanced to Spec G6.3 | 2000 FPM (or as specified) |

| Shaft Diameter Tolerance | -0.0005 / -0.0015 (Ex: 1.0" = 0.9995 / 0.9985) |

| End Cap | No end cap |

| Approximate Weight | 0.443 Pounds Per Inch (without shaft and bearings) |

4.5 x 2

| Finished Roll Diameter (Wide Web) | 4.550 / 4.420 in |

|---|---|

| Finished Roll Diameter (Narrow Web) | 4.330 / 4.310 in |

| Total Indicator Run Out (TIR) | 0.0005 Per Foot (0.002 Min) Ra |

| Surface Finish | 16, 32, 64, or 125 ra16, 32, 64, or 125 ra |

| Bore Available | WINlock Bore |

| Bearing Sizes Available | 1.0 in, 1.25 in, 25 mm1.0 in, 1.25 in, 25 mm |

| Bearing Type | Self Adjusting, ER, Free Spin |

| Balanced to Spec G6.3 | 2000 FPM (or as specified) |

| Shaft Diameter Tolerance | -0.0005 / -0.0015 (Ex: 1.0" = 0.9995/ 0.9985) |

| End Cap | Standard |

| Approximate Weight | 0.435 Pounds Per Inch (without shaft and bearings) |

4.5 x 3

| Finished Roll Diameter (Wide Web) | 4.550 / 4.420 in115.57/112.26 mm |

|---|---|

| Finished Roll Diameter (Narrow Web) | 4.330 / 4.310 in110.0/109.47 mm |

| Total Indicator Run Out (TIR) | 0.0005 Per Foot (0.002 Min) Ra |

| Surface Finish | 16, 32, 64, or 125 ra16, 32, 64, or 125 ra |

| Bore Available | WINlock Bore |

| Bearing Sizes Available | 1.5 in, 2.0 in, or 40 mm1.5 in, 2.0 in, or 40 mm |

| Bearing Type | Self Adjusting, ER, Free Spin |

| Balanced to Spec G6.3 | 2000 FPM (or as specified) |

| Shaft Diameter Tolerance | -0.0005 / -0.0015 (Ex: 1.0" = 0.9995/ 0.9985) |

| End Cap | No end cap |

| Approximate Weight | 0.473 Pounds Per Inch (without shaft or bearings) |

5 x 2

| Finished Roll Diameter (Wide Web) | 5.150 / 5.000 in |

|---|---|

| Finished Roll Diameter (Narrow Web) | 4.955 / 4.935 in130.8/127.00 mm |

| Total Indicator Run Out (TIR) | 0.0005 Per Foot (0.002 Min) Ra |

| Surface Finish | 16, 32, 64, or 125 ra16, 32, 64, or 125 ra |

| Bore Available | WINlock Bore |

| Bearing Sizes Available | 1.0 in, 1.25 in, 25 mm1.0 in, 1.25 in, 25 mm |

| Bearing Type | Self Adjusting, ER, Free Spin |

| Balanced to Spec G6.3 | 2000 FPM (or as specified) |

| Shaft Diameter Tolerance | -0.0005 / -0.0015 (Ex: 1.0" = 0.9995 / 0.9985) |

| End Cap | Standard |

| Approximate Weight | .502 Pounds Per Inch (without shaft or bearings) |

5 x 3

| Finished Roll Diameter (Wide Web) | 5.070 in /4.970 in128.77/126.24 mm |

|---|---|

| Finished Roll Diameter (Narrow Web) | 4.965 / 4.945 in126.04/125.53 mm |

| Total Indicator Run Out (TIR) | 0.0005 Per Foot (0.002 Min) Ra |

| Surface Finish | 16, 32, 64, or 125 ra16, 32, 64, or 125 ra |

| Bore Available | WINlock Bore |

| Bearing Sizes Available | 1.5 in, 2 in, 40 mm1.5 in, 2 in, 40 mm |

| Bearing Type | Self Adjusting, ER, Free Spin |

| Balanced to Spec G6.3 | 2000 FPM (or as specified) |

| Shaft Diameter Tolerance | -0.0005 / -0.0015 (Ex: 1.0" = 0.9995 / 0.9985) |

| End Cap | No end cap |

| Approximate Weight | 0.502 Pounds Per Inch (without shaft or bearings) |

6 x 2

6.190 / 6.000 in157.23/152.4 mm |

|

| Finished Roll Diameter (Narrow Web) | 5.980 / 5.960 in152.15/151.00 mm |

| Total Indicator Run Out (TIR) | 0.0005 Per Foot (0.002 Min) Ra |

| Surface Finish | 16, 32, 64, or 125 ra16, 32, 64, or 125 ra |

| Bore Available | WINlock Bore |

| Bearing Sizes Available | 1.0 in, 1.25 in, 25 mm1.0 in, 1.25 in, 25 mm |

| Bearing Type | Self Adjusting, ER, Free Spin |

| Balanced to Spec G6.3 | 2000 FPM (or as specified) |

| Shaft Diameter Tolerance | -0.0005 / -0.0015 (Ex: 1.0" = 0.9995 / 0.9985) |

| End Cap | Standard |

| Approximate Weight | 0.690 Pounds Per Inch (without shaft or bearings) |

6 x 3

| Finished Roll Diameter (Wide Web) | 6.100 / 5.990 in |

|---|---|

| Finished Roll Diameter (Narrow Web) | 5.970 / 5.950 in151.6/151.13 mm |

| Total Indicator Run Out (TIR) | Finished Roll Diameter (Wide Web) |

| Surface Finish | 16, 32, 64, or 125 ra16, 32, 64, or 125 ra |

| Bore Available | WINlock Bore |

| Bearing Sizes Available | 1.5 in, 2.0 in, 40 mm1.5 in, 2.0 in, 40 mm |

| Bearing Type | Self Adjusting, ER, Free Spin |

| Balanced to Spec G6.3 | 2000 FPM (or as specified) |

| Shaft Diameter Tolerance | -0.0005 / -0.0015 (Ex: 1.0" = 0.9995 / 0.9985) |

| End Cap | Standard |

| Approximate Weight | 0.693 Pounds Per Inch (Without shaft and bearings) |

8 x 3

| Finished Roll Diameter (Wide Web) | 8.100 / 7.925 in205.74/201.29 mm |

|---|---|

| Finished Roll Diameter (Narrow Web) | 7.835 / 7.815 in199.01/198.49 mm |

| Total Indicator Run Out (TIR) | 0.0005 Per Foot (0.002 Min) Ra |

| Surface Finish | 16, 32, 64, or 125 ra16, 32, 64, or 125 ra |

| Bore Available | WINlock Bore |

| Bearing Sizes Available | 1.5 in, 2.0 in, 40 mm1.5 in, 2.0 in, 40 mm |

| Bearing Type | Self Adjusting, ER, Free Spin |

| Balanced to Spec G6.3 | 2000 FPM (or as specified) |

| Shaft Diameter Tolerance | -0.0005 / -0.0015 (Ex: 1.0" = 0.9995/ 0.9985) |

| End Cap | Standard |

| Approximate Weight | 1.265 Pounds Per Inch (Without shaft and bearings) |

10 x 3

| Finished Roll Diameter (Wide Web) | 10.100 / 9.900 in256.54/251.46 mm |

|---|---|

| Finished Roll Diameter (Narrow Web) | 9.850 / 9.830 in250.19 /249.65 mm |

| Total Indicator Run Out (TIR) | 0.0005 Per Foot (.002 Min) Ra |

| Surface Finish | 16, 32, 64, or 125 ra16, 32, 64, or 125 ra |

| Bore Available | WINlock Bore |

| Bearing Sizes Available | 1.5 in, 2.0 in, 40 mm1.5 in, 2.0 in, 40 mm |

| Bearing Type | Self Adjusting, ER, Free Spin |

| Balanced to Spec G6.3 | 2000 FPM (or as specified) |

| Shaft Diameter Tolerance | -0.0005 / -0.0015 (Ex: 1.0" = 0.9995 / 0.9985) |

| End Cap | Standard |

| Approximate Weight | 1.481 Pounds Per Inch (Without shaft and bearings) |

- Battery

- Cardboard

- Flexible Packaging

- Food and Beverage

- Packaging

- Pharmaceutical

- Specialty Converting

- Tag and Label

Related Products

FIFE-500 Web Guiding System

Leverage the latest in web guiding technology and improve efficiency with the cost-effective FIFE-500, ideal for narrow web and nonwoven applications.

Control Series Electronic Knifeholders

Maximize operator safety, productivity and roll quality with Tidland’s Control Series. Features include an LED-backlit touchscreen interface, enhanced durability and available wireless operation.

Force5 Lightweight Air Chuck

The Force5 is incredibly durable in extreme conditions, retains its shape over time and is lightweight, making it an excellent alternative to aluminum chucks at the lowest market cost.

TS Load Cells

TS load cells provide the most consistent tension control regardless of temperature changes. They’re rugged and highly accurate, measuring tension in any unwind, rewind or intermediate web processing application.