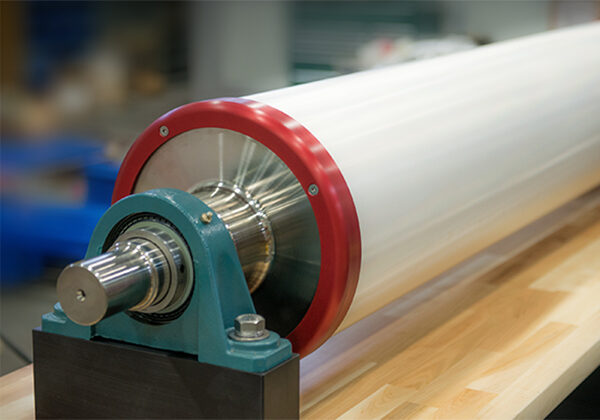

Vacuum Tension Rolls

WEBEX Vacuum Tension Rolls provide the ideal tension isolation and control point for your product. By pulling the web into intimate contact with the roll, Vacuum Tension Rolls increase friction forces that help prevent web slippage. Used ahead of flotation ovens or in coating lines where nipping or contacting both sides of the web is not possible or desired, Vacuum Tension Rolls are the solution for controlling your web.

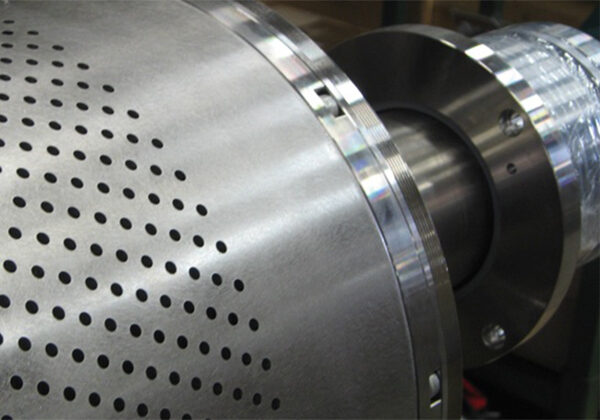

An ultra-fine, seamless nickel screen is available, which provides consistent grip across the entire width of the web, without damaging even the most delicate coated materials. Applications include the production of ultra-thin coated films, pressure-sensitive papers, decorative products, adhesive-coated films and optical film for the aerospace, biomedical and pharmaceutical industries.

Vacuum Tension Roll Options

- Fixed deckle or variable deckle

- Simply supported or cantilever

- Clean room design

- Custom vacuum connections

Vacuum Tension Rolls by WEBEX

WEBEX Vacuum Tension Rolls provide the ideal tension isolation and control point for your product. By pulling the web into intimate contact with the roll, Vacuum Tension Rolls increase friction forces that help prevent web slippage. Used ahead of flotation ovens or in coating lines where nipping or contacting both sides of the web is not possible or desired, Vacuum Tension Rolls are the solution for controlling your web.

An ultra-fine, seamless nickel screen is available, which provides consistent grip across the entire width of the web, without damaging even the most delicate coated materials. Applications include the production of ultra-thin coated films, pressure-sensitive papers, decorative products, adhesive-coated films and optical film for the aerospace, biomedical and pharmaceutical industries.

Webex Vacuum Rolls

| Nominal Roll Diameters (Standard Screens) | 8, 10.38, 12.75, 16 in203, 264, 324, 407 mm Non-standard diameters available |

|---|---|

| Minimum Face Length | 15 - 30 in380 - 760 mm Depending on diameter |

| Maximum Face Length | 156 in3,962.4 mm |

| Design Options | Fixed deckle or variable deckle |

| Typical Diametrical Tolerance | +/- 0.0005 in+/- 0.0013 mm |

| Typical Concentricity and Straightness Tolerance | +/- 0.0005 in+/- 0.013 mm |

| Finish | Nickel Plating |

| Base Materials | Aluminum, Stainless Steel, Carbon Steel |

Product Sheets

Request for Quote (RFQ)

- Packaging

- Cardboard

- Food and Beverage

- Flexible Packaging

- Pharmaceutical

- Battery

- Specialty Converting

Related Products

D-MAX Enhanced Web Guiding Controller

A compact and easy-to-use web guide controller that offers precise and reliable control for a variety of industrial applications.

Control Series Electronic Knifeholders

Maximize operator safety, productivity and roll quality with Tidland’s Control Series. Features include an LED-backlit touchscreen interface, enhanced durability and available wireless operation.

Lug Shafts

Tidland Lug Shafts are strong and versatile, delivering superior performance in the widest range of converting applications. Eliminate core damage, prevent roll slippage through fast startups and shutdowns and minimize vibration at high web speeds.

TS Load Cells

TS load cells provide the most consistent tension control regardless of temperature changes. They’re rugged and highly accurate, measuring tension in any unwind, rewind or intermediate web processing application.