Extending Die Life with ICD Technology

Maxcess rebuilds now incorporate ICD-exclusive, patented enhancements and precision processes to restore dies to peak performance and extend their working life.

Laser-Driven Bounce Detection Readiness

Our laser system detects die–anvil separation in < 0.25 seconds and lifts the die away, preventing catastrophic blade damage.

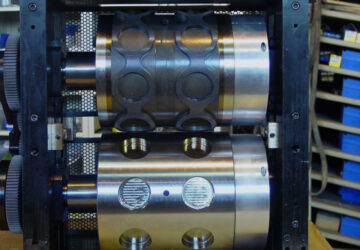

Patented Anti-Bounce Integration (US 11,292,146 B2)

Rebuilds can include ICD’s patented design that relocates pressure cylinders nearer the cut zone, virtually eliminating bounce.

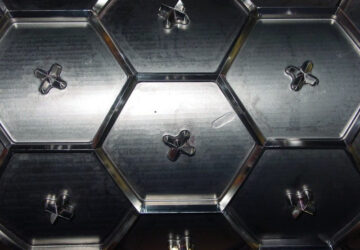

Extended-Life Edge Treatments

Extended-Life Edge Treatments

Common Issues We Fix

Even the highest-quality dies experience wear over time. Our technicians routinely address issues such as:

- Edge Chipping & Blade Wear – reclaim clean cuts and consistent depth.

- Misalignment or Roll Deformation – correct structural run-out

- Dulling & Underperformance – restore edge geometry and die speed

Additional Die Services

ICD offers specialized services to help you get the most from your rotary dies — from initial design to long-term performance and compliance.

Die Quality Assurance & Compliance

Ensure your dies meet strict quality and compliance standards with our precision inspection and certification services.

Die Product Evaluation

Receive a comprehensive assessment of die performance to identify wear, misalignment, or other issues before they affect production.

Custom Rotary Die Design Services

Collaborate with our engineering team to design dies tailored to your exact application, material, and production requirements.

Our Rebuild Process

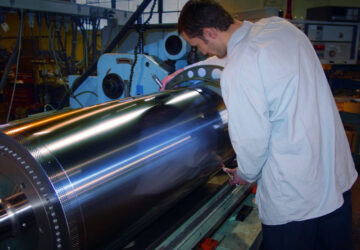

Every rebuild begins with a thorough inspection to assess damage, wear, and structural integrity. Our expert technicians utilize dimensional checks and visual analysis to develop a comprehensive action plan. Before rebuilding, we often recommend a thorough die product evaluation to assess wear, edge sharpness, and performance metrics.

Utilizing advanced machining tools and ICD’s proven sharpening techniques, we restore critical geometries and edges to their original tolerances.

We replace or recondition worn-out elements, such as anvil rolls, cutting blades, and bearing surfaces, to improve reliability and extend operational life.

Once rebuilt, each die undergoes rigorous testing to validate performance. We check alignment, run tolerances, and simulate real production conditions to ensure you’re ready to roll.

Rebuild vs. Replace: What’s Right for You?

When a rotary die begins to wear, you have two paths: restore the tool you own or replace it with a brand-new build. A professional rebuild typically saves 50–65% of the cost of a new die, often upgraded with ICD’s patented Anti-Bounce technology. If your material specs or cut patterns have changed, our custom die design service provides a clean-sheet solution that meets today’s tighter tolerances.

Cost Comparison

Upfront Cost

Professional rebuilds run 50–65 % less than purchasing a new die, freeing capital for other upgrades or spare tooling.

Downtime Impact

Typical turnaround is 7–10 days—far quicker than the 4–6-week lead time required for manufacturing a brand-new die.

Hidden Savings

Add coatings or patented anti-bounce upgrades during the rebuild, extending die life without paying the full replacement price.

ROI Tips

Calculate Lifetime Value

Compare rebuild cost to extra service life; many customers gain years of reliable output for a fraction of a new-die investment.

Track Performance After Rebuilds

Monitor scrap rate, uptime, and maintenance intervals to confirm performance gains and schedule the next service proactively.

Factor in Engineering Enhancements

Rebuilds allow geometry tweaks and bonding features for new materials, boosting throughput beyond the die’s original specification.

Get Started with a Rebuild

Ultimately, the decision to rebuild or replace depends on your production goals, budget, and operational timelines. With Maxcess and ICD’s combined expertise, we can help you in considering both options, evaluate your die, and offer honest, data-backed guidance on the best path forward.

Die Types We Repair & Rebuild

- Window Dies

- Patch Gummers

- Profile, Separating, or Patch Knives

- Tape Cylinders

- Score Shafts

- Gears & Coupling

- Bearing Blocks

- Custom Tooling Assemblies

Supported Die Materials

Tungsten Carbide

Superior wear resistance and high-cut count longevity.

Powdered Metal

Cost-effective performance for common converting applications.

Tool Steel

Durable and economical option for consistent performance across a variety of materials.

Ready to Upgrade Instead of Replace?

If your production goals or materials have changed, we’ll help you spec out a smarter custom die through our Custom Die Design Services. See how custom design can outperform OEM replacements.

ICD: Over 40 Years of Precision Rebuilding

Why Maxcess + ICD?

International Cutting Die has been rebuilding, repairing, and enhancing rotary tooling for over four decades. We have rebuilt thousands of rotary dies worldwide, extending average tool life by 65 percent. Now part of Maxcess, ICD continues to bring its trusted expertise to converters worldwide, backed by expanded capabilities and streamlined service.

- Price: Cost-efficient rebuilds vs. full replacements

- Quality: Proven ICD craftsmanship & technology

- Service: Fast turnaround, data-driven recommendations