Anodized Coatings

Anodized coatings extend roller life by improving wear resistance, corrosion protection, and surface performance. Whether you need Type II for cost-effective upgrades or Type III Hard Coat for extreme applications, Componex has a solution built for your web handling challenges.

- Improved abrasion resistance and durability

- Enhanced corrosion protection

- Available in Type II clear or black anodize; custom colors by request

- Available in Type III Natural or black

- Sealed with Nickel Fluoride Acetate or Teflon (PTFE)

Anodized Roller Coatings for Durability & Abrasion Resistance

Anodized roller coatings by Componex provide a cost-effective way to extend the life of your idlers. By forming a hard aluminum oxide surface, these coatings protect against scratching, wear, and abrasive materials that can shorten roller service life.

These coatings are available in both Type II and Type III hard coats, with the option to add black dye and PTFE impregnation, further enhancing durability, reducing friction, and optimizing roller performance.

Type II Anodize

Type II Anodize is a cost-effective upgrade from bare aluminum, offering good corrosion resistance and a smoother surface.

Common Applications for Type II Anodize

- Printing

- Food Packaging

- Visual Identification (Color)

Type III Anodize

Type III Hard Coat Anodize delivers maximum wear resistance, higher heat tolerance, and longer life in demanding web handling environments.

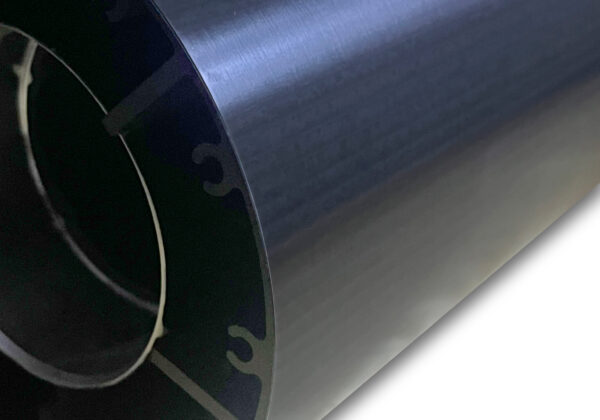

Componex's standard offering is Type III Black Hard Coat. Being an extruded tube, WINertia rolls with a natural hard coat will leave the die line faintly visible through the hard coat. By dying the anodized black, it gives the roller a dark, uniform color. The visual die lines are only cosmetic and have no effect on performance.

Common Applications for Type III Anodize

- White Inks containing Titanium dioxide

- Printing

- Laminating

- Ovens

- Abrasives webs

Type III Hard Coat with Superfinishing

Type III Hard Coat with Superfinishing offers the same wear resistance with a finish of 2-6 Ra. Use in slow-speed applications where warm webs are prone to imprinting.

Common Applications for Type III Hard Coat with Superfinishing

- Slow-running webs

- Cast Film Lines

- Ovens

Request a Quote

Maximize roller life and performance with anodized roller coatings. Contact Maxcess to speak with an application specialist or request a quote.

-

Anodized Coating Options

Feature Type II Anodize Type III Hard Coat Coating Thickness ~0.0005" - 0.0010" ~0.002" Hardness ~300-400 HV ~400-600 HV Durability Moderate Very high; heavy duty Corrosion Resistance Good (sealed) Excellent (sealed) Colors Available Clear, Black, Custom Natural, Black Available Sealants Nickel Fluoride Acetate Nickel Fluoride Acetate, Teflon (PTFE) Operating Temp Up to ~200°F Up to ~450°F* Applications Low speed, printing, packaging High speed webs, laminating, ovens

Related Products

Advantage Series Knifeholder

Delivering a high slit quality and extended blade life, Tidland’s Advantage Series provides a minimum slit width of only 19.5 mm (0.768 inches).

RotoRepel™ Adhesive Control Treatment

RotoRepel™ offers comprehensive adhesive control benefits far beyond nonstick properties, improving overall die and press performance in several ways for more longevity and better efficiency.

FIFE-500 Web Guiding System

Leverage the latest in web guiding technology and improve efficiency with the cost-effective FIFE-500, ideal for narrow web and nonwoven applications.

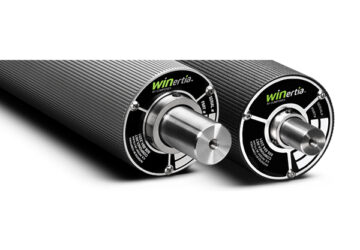

WINertia™ AV-Air Vent Aluminum Dead Shaft Idler

WINertia™ AV-Air Dead Shaft Idlers eliminate entrapped air 7.5x faster, ensuring wrinkle-free web handling, stable tension, and optimal performance for high-speed converting and printing lines.

Valley Roller Rubber Covered Roll Solutions

Valley Roller’s rubber-covered rollers and nip rolls are custom-engineered using over 3,000 proprietary rubber compounds to deliver optimal traction, tension control, and durability. Ideal for high-speed web handling applications such as converting, laminating, printing, and embossing, each roll is precision-ground to meet exacting industry standards and can be refurbished or recoated to extend lifespan.