Componex End Cap Serial Customization

Ensure every roller is protected, traceable, and branded with Componex End Cap Customization.

- Clear documentation of Componex job number and customer part number

- Direct access to balancing data and quality control reports

- Protects precision bearings from dust, debris, and contaminants

- OEM branding options with logos and contact details

- Streamlined customization process managed by Maxcess engineers

- Simplifies re-ordering and ensures long-term traceability

Componex End Cap Serial Customization Overview

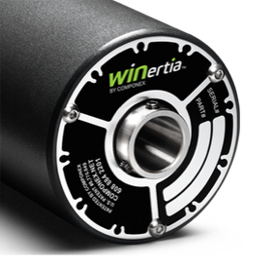

The Componex end cap is more than just a cover–it’s an essential identification and protection tool for your rollers. Every standard end cap clearly displays both the Componex job number and your customer part number, creating a direct link to balancing data and quality control reports. This ensures traceability and simplifies the re-ordering process.

In addition to functionality, the end cap is critical in protecting the life of your rollers. By shielding precision bearings from dust, dirt, and other contaminants it helps extend bearing performance and reduces the risk of premature failure.

For OEM partners, Maxcess offers custom end cap branding, including logos and product details, helping manufacturers reinforce their identity with every roll shipped.

Key Benefits

- Enhanced Traceability: Job and part numbers provide instant access to roller history, QC reports, and balancing data.

- Improved Bearing Protection: Shields bearings from contaminants that reduce performance and longevity.

- OEM Branding Options: Add logos, product details, or contact information to create a professional, branded look.

- Simplified Reordering: Serial customization ensures faster, more accurate replacement ordering.

- End-to-End Support: Maxcess manages the full customization process, including artwork, proofs, and lead times.

Configuration Options

Maxcess provides flexible end cap solutions to meet your operational and branding needs:

- Standard End Cap: Includes Componex job number and customer part number for full traceability.

- Customized OEM End Cap: Add your logo, product details, and branding elements for a consistent market presence.

- Various Sizes & Styles: End caps available to match multiple roller designs and applications.

Request a Quote

Ready to customize your Componex end caps? Contact Maxcess to speak with an engineer about your needs, review customization options, or request a quote.

Related Products

WINertia™ AV-Air Vent Aluminum Dead Shaft Idler

WINertia™ AV-Air Dead Shaft Idlers eliminate entrapped air 7.5x faster, ensuring wrinkle-free web handling, stable tension, and optimal performance for high-speed converting and printing lines.

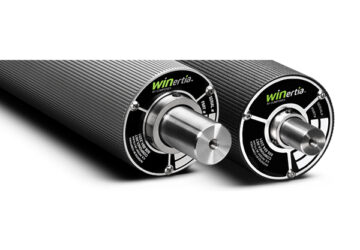

Componex WINertia™ Aluminum ST Smooth Tubing Idler Rolls

The WINertia™ Aluminum ST Smooth Tubing Idler Rolls by Componex offers up to 30% less rotational inertia than standard aluminum idlers. Featuring WINlock™ protection and self-aligning bearings, it delivers smooth performance, easy installation, and long-term durability for fast-paced converting and packaging lines.