WEBEX Stainless Steel Live Shaft Idler Rolls

Engineered for extreme environments, WEBEX Stainless Steel Live Shaft Idlers are built to perform where standard idlers fail. Designed to handle harsh chemicals, high heat, and corrosive conditions, these idlers deliver consistent, reliable performance in the most demanding web handling applications.

Benefits of Live Shaft Steel Idlers:

- Withstands corrosive chemicals and high-moisture environments

- Handles elevated temperatures with proper venting

- Designed for minimal wear in abrasive, high-load applications

- Available with optional coatings for added durability and performance

Reliable Performance in Harsh Conditions

WEBEX Stainless Steel Live Shaft Idler Rolls are the go-to solution when web integrity and roll performance are at risk due to environmental factors. Whether you're running PVC webs that produce corrosive byproducts or operating in high-moisture or chemical-laden environments, these idlers are designed to resist rust, corrosion, and contamination.

They are available in various stainless steel grades and optional coatings, such as electroless nickel, chrome, or plasma-applied tungsten carbide, for added protection. This makes them ideal for applications where chemicals, dust, or vapors would otherwise destroy conventional dead shaft bearings.

Strong Load Bearing

Designed with durable 304 and 300-series stainless steel materials, these live shaft idlers are capable of supporting heavy loads in rugged production environments. The precision-machined tubing ensures structural integrity with minimal stock removal, enhancing roll balance and overall load-handling capabilities.

Smooth Surface Finish

Available with advanced surface options—such as chrome machined finishes, matte textures, and grooved patterns—WEBEX idlers offer superior web control and smooth material transport. Optional grooves, such as spiral “V”, herringbone, or micro-groove designs, improve traction, alignment, and web handling consistency.

Minimal Wear

To ensure long-term performance, these idlers are designed to minimize wear even under constant exposure to harsh conditions. Bearings are strategically positioned outside the direct web path to reduce contamination. Optional coatings, such as high-release tungsten-carbide (plasma) or rubber coverings, extend service life while reducing maintenance.

Featured Products

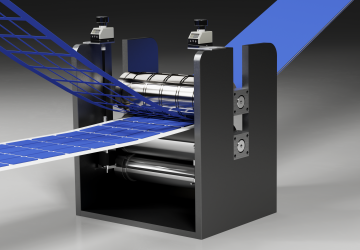

RotoAdjust Dual Adjustable Anvil

The new RotoAdjust offers state-of-the-art Industry 4.0 automation and data analytics to run better, faster, and smarter. Unlock tomorrow’s automation potential today.

AccuAdjust Dual Adjustable Anvil

AccuAdjust solves liner variability issues and allows easy cutting of PET, Glassine, Kraft and more with a simple turn of a precision digital dial. Cut perfect labels and minimize material consumption no matter the liner material.

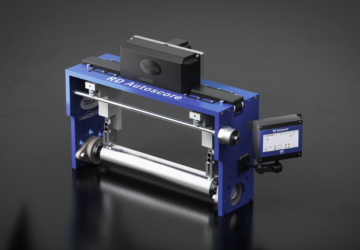

RD AutoScore

Keep operators safe and reduce setup time with the Tidland RD AutoScore system.

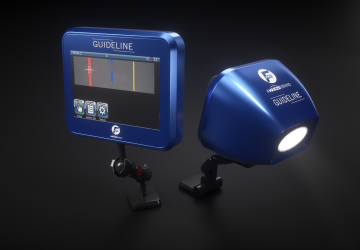

GuideLine & Guideline High Resolution (HR) Digital Line Guide Sensor Overview

Detect lines, edges of lines, graphic patterns, and more where traditional line sensors don’t work at a competitive price point. The GuideLine is suitable for the most demanding line guide applications.