RotoAdjust Dual Adjustable Anvil

Cut perfect labels, no matter the liner material- designed for liners like PET, Glassine and Kraft

Advanced Industry 4.0 analytics, monitoring and operator alerts

Single or dual bearer adjustment for increased flexibility in die cutting

Easy job setup and recall for anvil clearance level, average speed of press and components used

Global support, local response

RotoAdjust Dual Adjustable Anvil Overview

RotoMetrics, a Maxcess brand, gives you the power to control liner variation with ease. With the next-generation of skilled labor entering the market, as well as liner variability and substitutions at an all-time high, press operators need a solution to control variability that’s both easy to use and extremely accurate.

The new RotoAdjust offers state-of-the-art Industry 4.0 automation and data analytics to run better, faster and smarter. Featuring plug-and-play automation, job storing and recall and advanced IOT software that monitors your die station performance and alerts your operators when critical maintenance needs arise, the new RotoAdjust let’s you unlock tomorrow’s automation potential today!

Product Sheets

Related Products

AccuStar® UltraFilm™ Flexible Die (Film Applications)

The AccuStar™ UltraFilm™ is considered the “all-star” of RotoMetrics’ flexible die solutions featuring the exacting precision tolerances required to convert the most challenging films and liners in today’s market.

RotoRepel™ Adhesive Control Treatment

RotoRepel™ offers comprehensive adhesive control benefits far beyond nonstick properties, improving overall die and press performance in several ways for more longevity and better efficiency.

Anvils

Unlock the power of precision with our anvil solutions by RotoMetrics. Choose from a range of solutions, including Base Anvils, Adjustable Clearance Anvils and AccuAdjust, RotoAdjust Dual Adjustable Anvils.

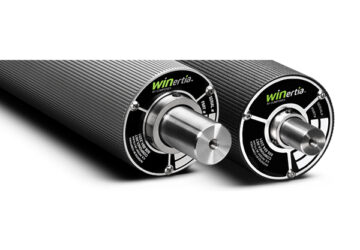

WINertia™ AV-Air Vent Aluminum Dead Shaft Idler

WINertia™ AV-Air Dead Shaft Idlers eliminate entrapped air 7.5x faster, ensuring wrinkle-free web handling, stable tension, and optimal performance for high-speed converting and printing lines.