ICD Exclusive Technologies We Use for Die Product Evaluation

Maxcess now brings ICD’s advanced detection systems and patented engineering insights to deliver a complete picture of die condition and performance.

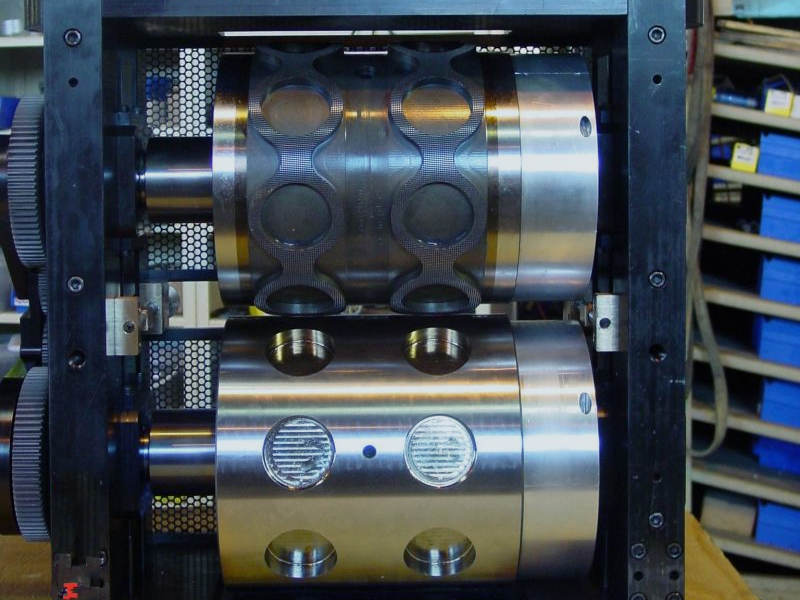

Laser-Driven Bounce Detection

Our laser system detects die–anvil separation in less than 0.25 seconds, lifting the die away to prevent catastrophic blade damage. This data is incorporated into your evaluation report to identify bounce risks.

Patented Anti-Bounce Technology (US 11 292 146 B2)

We assess whether relocating pressure cylinders nearer the cut zone could reduce bounce and improve cut consistency in your operation.

Why Die Evaluation & Reverse Engineering Matters

- Early Detection of Wear & Failure – Prevent unplanned downtime and costly scrap.

- Consistent Output & Quality – Maintain cut depth, edge integrity, and register control.

- Lower Total Cost of Ownership – Extend tool life and delay capital purchase cycles.

- Compliance & Traceability – Generate a data-backed report for ISO, medical, or food-grade audits.

Our Die Evaluation Services

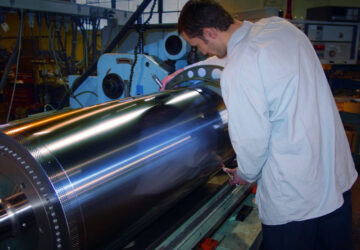

Visual Inspection & Dimensional Analysis

Our experts conduct thorough visual inspection and precise measurements to detect signs of wear, damage, or deviations from specifications.

Performance Benchmarking

We assess your die’s performance against industry standards and historical data to identify areas for improvement.

Material Compatibility Assessment

Evaluating the interaction between your dies and materials ensures optimal performance and prevents premature wear.

Wear Pattern Diagnostics

Analyzing wear patterns helps pinpoint underlying issues, allowing for targeted interventions to enhance die longevity.

Reverse Engineering & Print Recreation

Need a die reproduced? We use 3D scanning, CAD modeling, and precision machining to recreate dies when documentation is lost or legacy dies need upgrading.

Change Tooling Compatibility Across Machines

- Window Dies

- Patch Gummers

- Profile, Separating, or Patch Knives

- Tape Cylinders

- Score Shafts

- Gears & Coupling

- Bearing Blocks

- Custom Converting Components

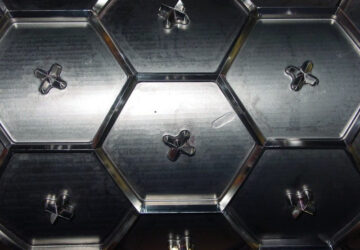

Die Chemistry Options

We offer evaluation and reverse engineering for dies manufactured in:

Tungsten Carbide

Ultra-durable and wear-resistant for abrasive materials

Powdered Metal

Versatile and cost-effective with balanced performance

Tool Steel

Durable and economical option for consistent performance across a variety of materials

Who Should Use This Service?

From OEMs to converters, evaluation & reverse engineering reduce downtime and unlock data-driven upgrades for:

- OEMs Managing High-Volume Converting Lines: Ensure your equipment operates at peak efficiency to meet production demands.

- Packaging Manufacturers Experiencing Die Downtime: Identify and address issues causing unexpected stoppages.

- Nonwoven Material Processors: Optimize die performance for specialized materials and applications.

Additional ICD Services

Pair your evaluation with complementary services that implement recommendations and verify results.

Die Rebuilding & Repair

Restore edge geometry, correct misalignment, and extend die life with our patented Anti-Bounce upgrades.

Die Quality Assurance & Compliance

Ensure your dies meet strict specifications and regulatory standards through precision inspection and certification.

Custom Rotary Die Design

Get dies engineered for your exact materials, tolerances, and production speeds—optimized from day one.

Integrated with Rebuilding & Redesign

What Happens After Your Evaluation?

Option 1 — Rebuild & Repair.

ICD technicians restore geometry, sharpen blades, and add patented anti-bounce upgrades — saving 50-65 % versus a new die.

Option 2 — Custom Die Redesign.

Need new specs or materials? We reverse-engineer your current die and deliver a brand-new, production-ready design in as little as 3 weeks.

Based on your evaluation results, we may recommend services such as Die Rebuilding & Repair, Die Quality Assurance & Compliance, or advanced Die Chemistry Options to enhance durability and maintain peak performance.

A Legacy of Precision Powered by ICD

For more than 40 years, ICD has set the standard for engineered rotary dies in converting industries worldwide. Now part of the Maxcess family, ICD continues to lead with specialized tooling for paper, film, foil, nonwoven, and medical applications, delivering precision rotary tooling for over five decades, with thousands of evaluations performed globally each year.

Contact International Cutting Die

Ready for a Die Checkup?

Get ahead of costly downtime and performance issues. Our experts are ready to evaluate your die systems and recommend the upgrades you need to stay sharp and competitive.