WINtrac™ Coatings

- Enhanced Traction: Improves web handling and reduces slippage

- Non-abrasive Surface: Protects delicate materials from scuffing or scratching

- Durable Performance: Designed to withstand demanding converting environments

- Reduced Downtime: Minimize web breaks and improve line efficiency

WINtrac™ Coatings for Traction & Inline Integration

Ultra-High Release Idler Roll Coatings for Ink & Adhesive Applications

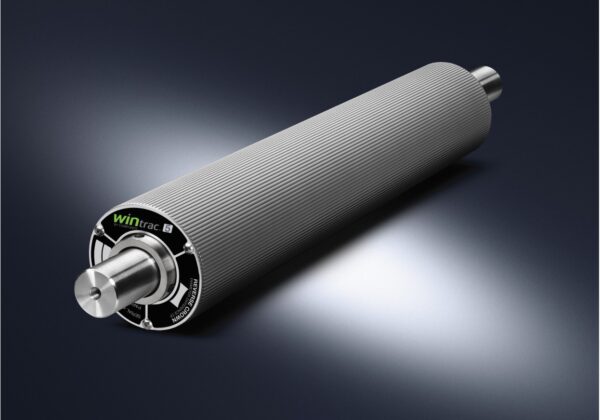

The revolutionary WINtrac™ coatings are formulated for a wide range of web handling applications, including printing and adhesive applications. This unique coating process was primarily designed to complement and enhance WINertia™ aluminum idler rollers.

The WINtrac™ coating is directly integrated with the WINertia™ aluminum idler roller manufacturing process. We eliminate the outsourcing time generally associated with coating rollers. As a result, we provide customers with the highest quality coated rolls at a competitive price. This inline integration also allows for a short lead time. WINtrac™ coated rolls are manufactured just as quickly as an uncoated roll – just 5 business days!

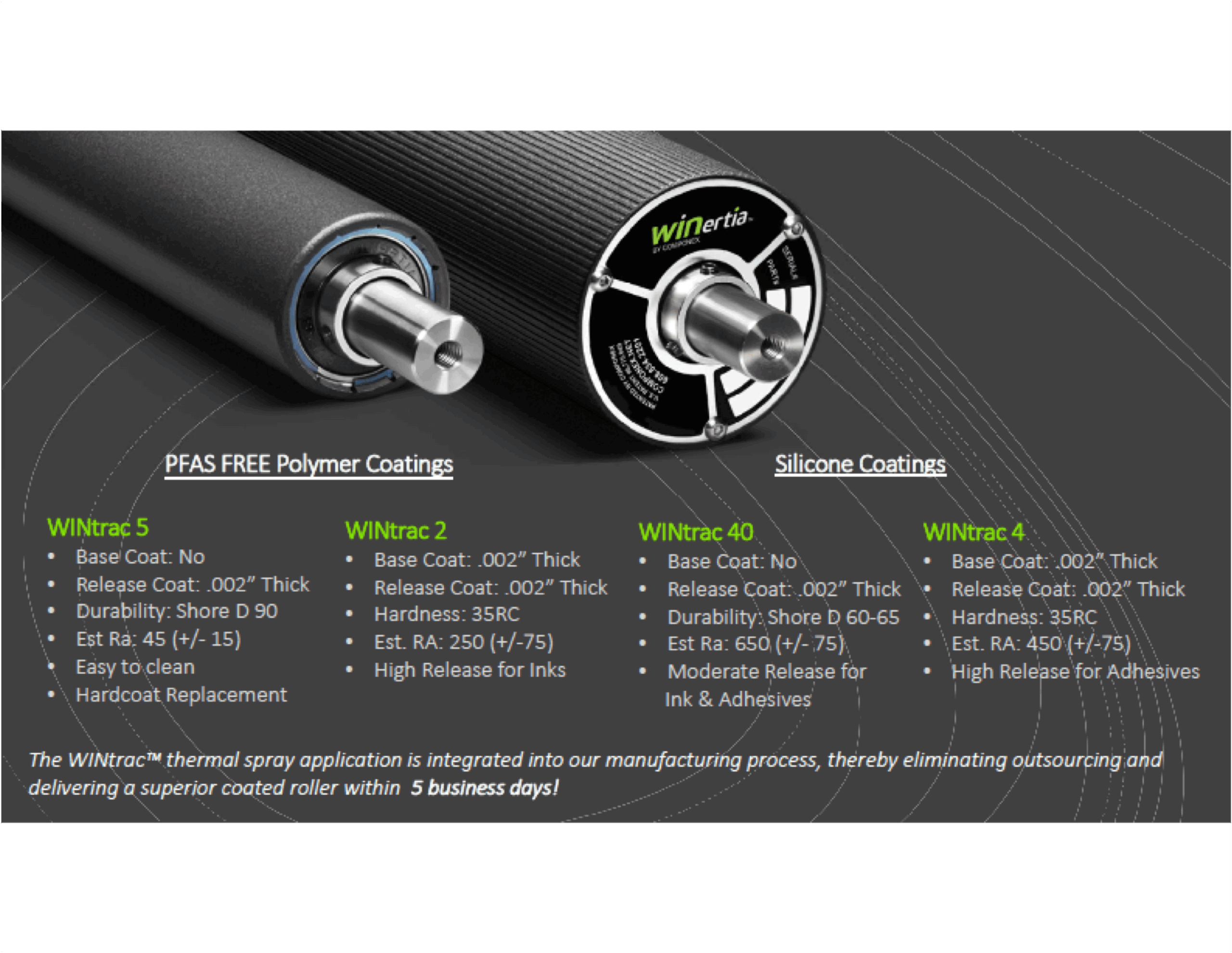

WINtrac™ 5 & WINtrac™ 40 Coatings

WINtrac™ 5 — Ultra Smooth Release ***NEW – PFAS FREE FORMULA ***

Our WINtrac 5 is our ultimate releasing coating yet! This coating is designed for easy roller clean up – ink wipes off easily. Now with an improved release for adhesives. The WINtrac 5 features a high-performance, durable coating delivering corrosion resistance and superior cleanability. This coating is also recommended as an alternative to hardcoat. WINtrac 5 is now available on AV and smooth rollers!

WINtrac™ 40 — High Traction Adhesive Release

The new WINtrac 40 is designed for idler applications where aggressive adhesive surfaces come in contact with the WINertia idler. A proprietary high-release silicone top coating is applied to provide ultimate adhesive release while maintaining traction. This release coating has also been tested for ink release with positive results!”

WINtrac™ 2 & WINtrac™ 4 Coatings

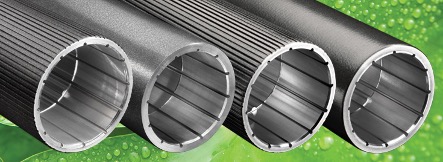

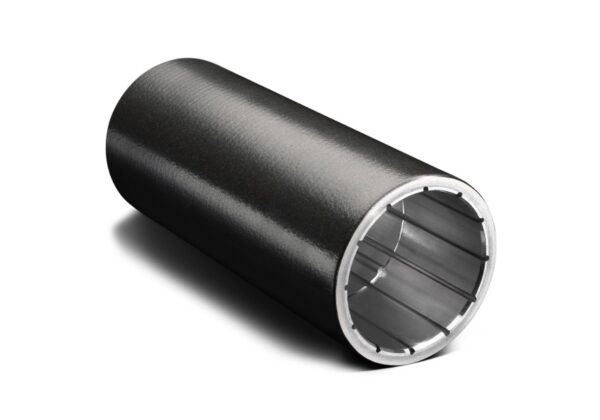

WINtrac 2 and WINtrac 4 thermal spray features a revolutionary surface design that delivers greater durability and exceptional release.

WINtrac™ 2

WINtrac™ 2 is a two-step thermal spray coating process. A durable PFAS-free top coat is applied over the metalized base coating to achieve optimum release for ink applications. The surface can be easily cleaned without rubbing off the surface top coat. This exclusive process provides enhanced wear resistance compared to the competition.

WINtrac™ 4

WINtrac™ 4 is a two-step thermal spray coating process. A silicone high-release top coat is applied over the metalized base coating to achieve optimum release for ink or adhesive applications.

Common Applications

- Label and packaging production

- Film and foil converting

- Paper processing

- Flexible packaging

- Web guiding and winding applications

Roller Compatibility

WINtrac™ coatings are directly integrated with the WINertia™ aluminum idler rolls manufacturing process, eliminating the outsourcing time normally associated with coating rollers. As a result, we provide customers with the highest quality coated rolls at the lowest possible price. Inline integration also allows for a short lead-time–WINtrac™ coated rolls are manufactured in just five business days.

Request a Quote

Our WINertia Idler Application Specialists are available to help you select the correct WINtrac™ coating to match your idler roller needs. You can take advantage of our years of experience in manufacturing idler rolls by contacting Maxcess to speak directly with one of our Application Specialists.

WINtrac Coatings Comparison

| WINtrac 2 | Base Coat: Microgroove Thermal Spray |

|---|---|

| WINtrac 4 | Base Coat: Microgroove Thermal Spray |

| WINtrac 5 AV / 5 ST | Base Coat: Microgroove |

| WINtrac 40 | Base Coat: Microgroove |

Related Products

Advantage Series Knifeholder

Delivering a high slit quality and extended blade life, Tidland’s Advantage Series provides a minimum slit width of only 19.5 mm (0.768 inches).

RotoRepel™ Adhesive Control Treatment

RotoRepel™ offers comprehensive adhesive control benefits far beyond nonstick properties, improving overall die and press performance in several ways for more longevity and better efficiency.

FIFE-500 Web Guiding System

Leverage the latest in web guiding technology and improve efficiency with the cost-effective FIFE-500, ideal for narrow web and nonwoven applications.

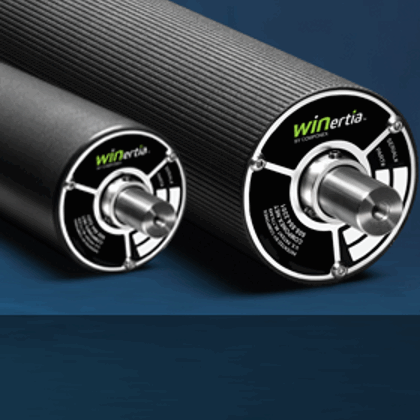

WINertia™ AV-Air Vent Aluminum Dead Shaft Idler

WINertia™ AV-Air Dead Shaft Idlers eliminate entrapped air 7.5x faster, ensuring wrinkle-free web handling, stable tension, and optimal performance for high-speed converting and printing lines.

Valley Roller Rubber Covered Roll Solutions

Valley Roller’s rubber-covered rollers and nip rolls are custom-engineered using over 3,000 proprietary rubber compounds to deliver optimal traction, tension control, and durability. Ideal for high-speed web handling applications such as converting, laminating, printing, and embossing, each roll is precision-ground to meet exacting industry standards and can be refurbished or recoated to extend lifespan.