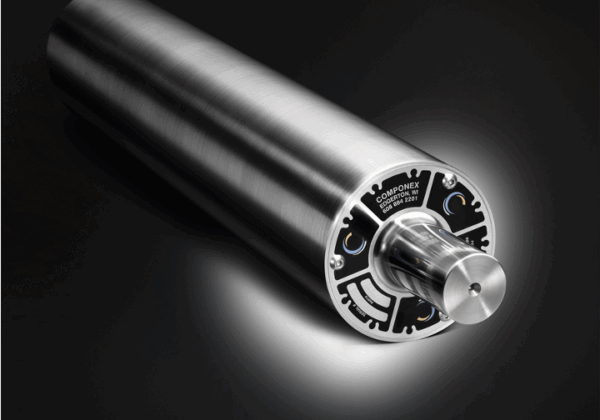

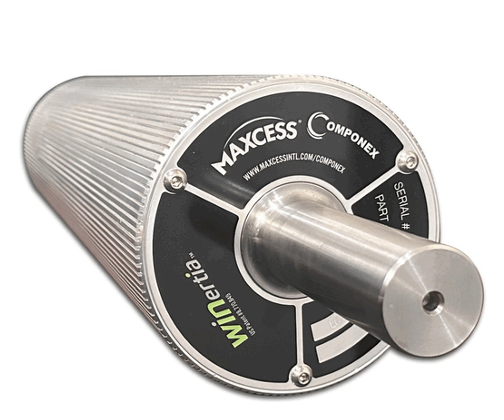

Componex WINertia™ Aluminum Live Shaft Idler

- Available in WINertia ST or AV

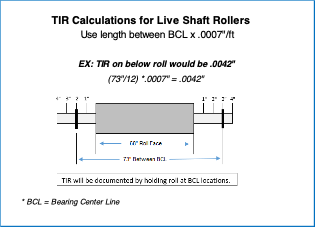

- Dynamically 3D balanced to reduce whip and vibration

- Lightweight aluminum core for faster acceleration and deceleration

- Wide range of diameters, lengths, coatings, and finishes available

- WINertia AV gives you the necessary traction for driven applications

WINertia™ Aluminum Live Shaft Idler Overview

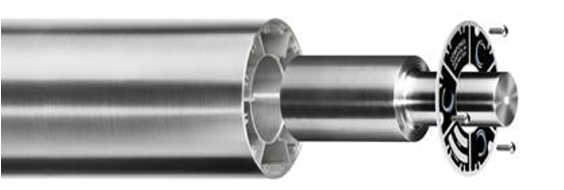

The Componex WINertia™ Aluminum Live Shaft roll provides a simple, cost-effective solution for demanding web handling applications. Utilizing the benefits of WINertia tubing, dynamic 3D balancing, and pressed-in journal design, this roll gives your application an edge over the competition.

Key Benefits

- High-speed stability with full-length dynamic balancing

- Lightweight aluminum tubing for improved energy efficiency

- Withstands harsh environments better than dead-shaft rollers

- Easy maintenance with bearings mounted directly to the machine frame

- Multiple coating and covering options for application versatility

- Available with 1144 steel or T303 stainless journals

- Journal fit tested to withstand an applied torque of 1,000 lb-ft

Common Applications

- High-speed converting operations

- Printing and packaging processes

- Applications requiring a higher load capacity than dead-shaft idlers

- Driven applications where precision and stability are critical

Configuration Options

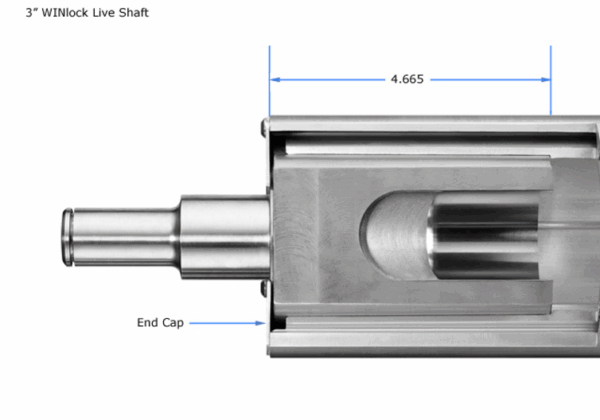

- Diameters: 3” to 10”

- Lengths: 12” to 158”

- Journal Protrusion: up to 12”

- Multiple Coatings: Bare aluminum, WINtrac Coatings, Plasma Cover, Anodized, or Rubber Coverings

- Journal Material Options: 1144 Steel or T303 Stainless Steel

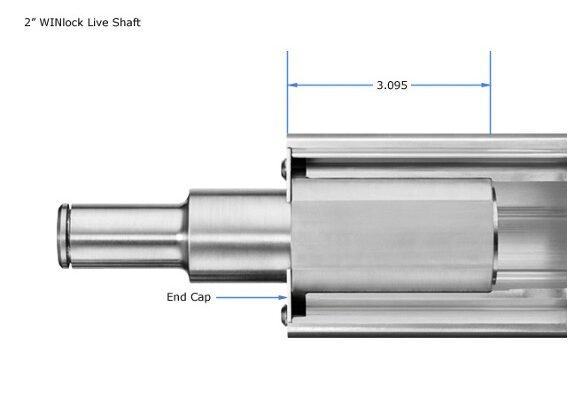

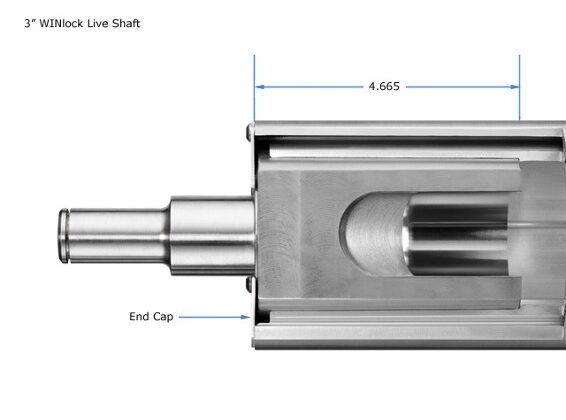

- Balancing and end caps consistent with WINertia™ dead shaft rollers

- Available in a High-Temp version for applications up to 450°F

- Available in WINertia ST or AV

- Optional Superfinishing for improved surface finish (4-6 Ra)

Request a Quote

Contact Maxcess to discuss your process needs and learn how the WINertia Aluminum Live Shaft Idler can improve your line’s performance and reliability.

| Standard 3 x 2 | Finished Roll Diameter: 3.175 / 3.075 in |

|---|---|

| AV 3 x 2 | Finished Roll Diameter: 3.140 / 3.020 in |

| AV 3.5 x 2 | Finished Roll Diameter: 3.540 / 3.450 in |

| Standard 4 x 2 | Finished Roll Diameter: 4.050 / 3.970 in |

| AV 4 x 2 | Finished Roll Diameter: 4.100 / 3.970 in |

| Standard 4 x 3 | Finished Roll Diameter: 4.150 / 4.075 in |

| AV 4 x 3 | Finished Roll Diameter: 4.200 / 4.060 in |

| AV 4.5 x 2 | Finished Roll Diameter: 4.550 / 4.330 in |

| Standard 4.5 x 3 | Finished Roll Diameter: 4.500 / 4.290 in |

| AV 4.5 x 3 | Finished Roll Diameter: 4.550 / 4.330 in |

| Standard 5 x 2 | Finished Roll Diameter: 5.110 / 4.900 in |

| AV 5 x 2 | Finished Roll Diameter: 5.150 / 4.950 in |

| Standard 5 x 3 | Finished Roll Diameter: 4.050 / 4.870 in |

| AV 5 x 3 | Finished Roll Diameter: 5.070 / 4.950 in |

| Standard 6 x 2 | Finished Roll Diameter: 6.100 / 5.810 in |

| AV 6 x 2 | Finished Roll Diameter: 6.190 / 5.970 in |

| Standard 6 x 3 | Finished Roll Diameter: 6.080 / 5.870 in |

| AV 6 x 3 | Finished Roll Diameter: 6.100 / 5.960 in |

| Standard 8 x 3 | Finished Roll Diameter: 8.000 / 7.520 in |

| AV 8 x 3 | Finished Roll Diameter: 8.100 / 7.820 in |

| Standard 10 x 3 | Minimum Face Length = 32" |

| AV 10 x 3 | Minimum Face Length = 32" |

Featured Products

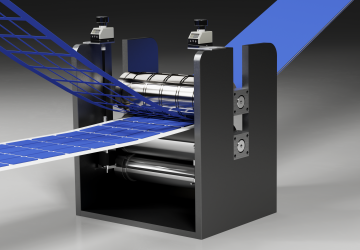

RotoAdjust Dual Adjustable Anvil

The new RotoAdjust offers state-of-the-art Industry 4.0 automation and data analytics to run better, faster, and smarter. Unlock tomorrow’s automation potential today.

AccuAdjust Dual Adjustable Anvil

AccuAdjust solves liner variability issues and allows easy cutting of PET, Glassine, Kraft and more with a simple turn of a precision digital dial. Cut perfect labels and minimize material consumption no matter the liner material.

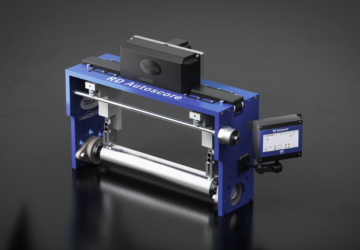

RD AutoScore

Keep operators safe and reduce setup time with the Tidland RD AutoScore system.

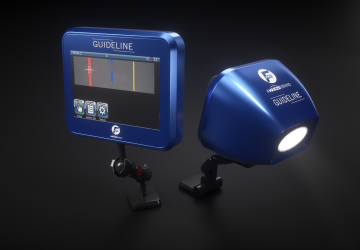

GuideLine & Guideline High Resolution (HR) Digital Line Guide Sensor Overview

Detect lines, edges of lines, graphic patterns, and more where traditional line sensors don’t work at a competitive price point. The GuideLine is suitable for the most demanding line guide applications.