Over 20 Years of Rotary-Die Innovation

From a small Chicago shop to a globally recognized converting partner, ICD has spent decades pioneering smarter, stronger rotary tooling solutions.

ICD Timeline: Over 20 Years of Rotary-Die Innovation

2002

ICD founded – Melrose Park, IL →

2010

Expanded Melrose Park operations by opening new facility adding 42k sq. ft →

2020

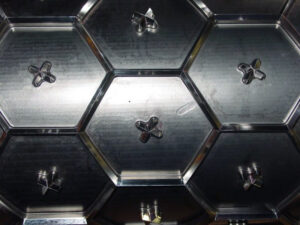

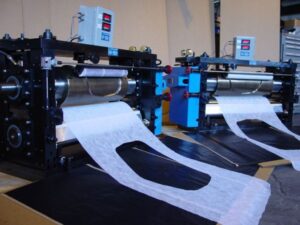

Greatly impacted PPE supply during COVID pandemic – N95 facemask die station →

2022

Anti-Bounce patent (#US 11 292 146 B2) →

2024

Acquired by Maxcess →

Patented Technologies That Set ICD Apart

ICD’s innovations eliminate catastrophic bounce events and unlock higher line speeds—proactively protecting tooling even in demanding web conditions.

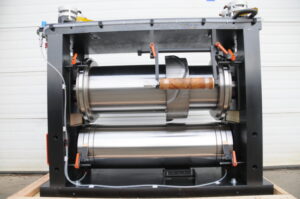

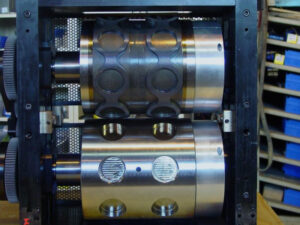

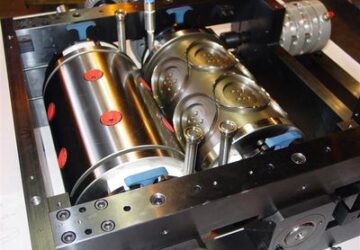

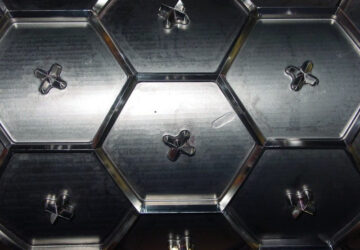

Anti-Bounce Technology

Re-positions pressure cylinders nearer the cut zone, eliminating vibration and

boosting output.

Patent US 11 292 146 B2

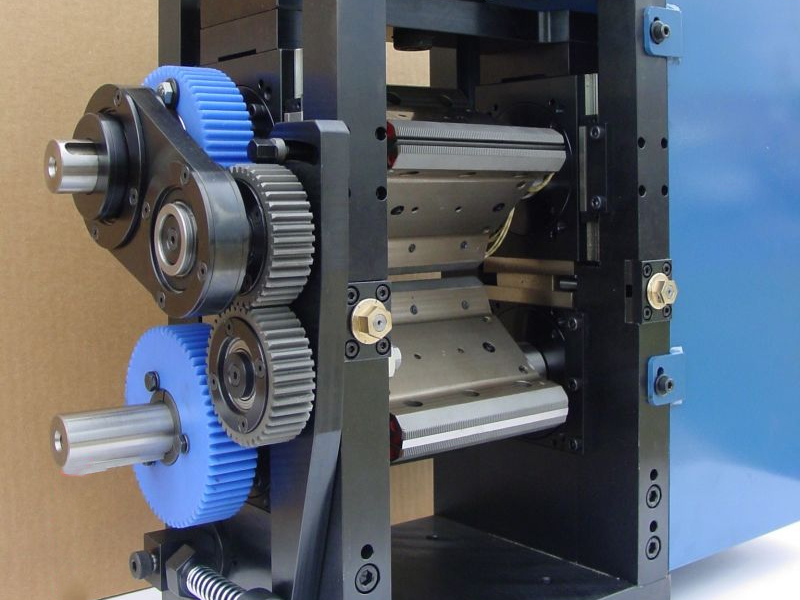

Laser-Driven Bounce Detection

Detects die–anvil separation in < 0.25 s, lifts the die away to prevent

catastrophic damage, and records a data log for QA.

Other Rotary Die Services

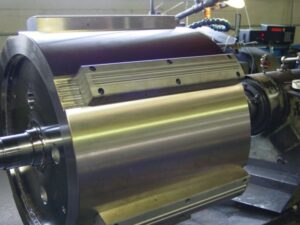

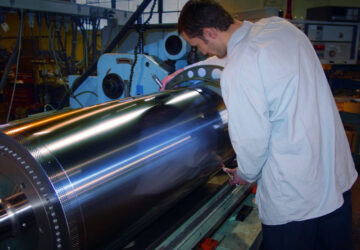

Die Rebuilding & Repair

Save 50 – 65 % versus buying new. Our technicians resharpen blades, re-calibrate tolerances, and add patented Anti-Bounce upgrades.

Die Quality Assurance & Compliance

ICD applies precision measurement tools and patented detection systems to verify that every die meets exacting specifications before and after installation.

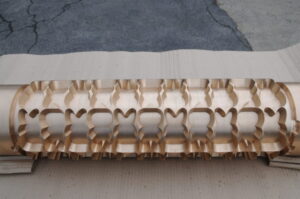

Die Product Evaluation

Laser diagnostics uncover wear, run-out, and bounce events. Receive a PDF report, ISO-ready calibration certificate, and CAD model for reverse engineering.

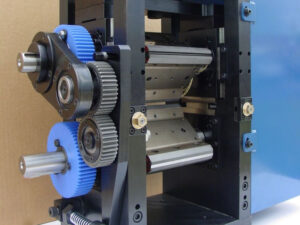

Custom Rotary Design

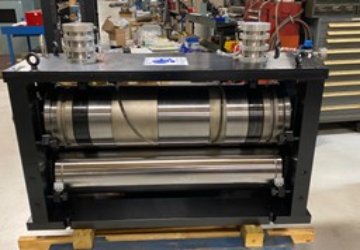

ICD integrates proven design principles, sensor readiness, and materials engineering to produce high-precision dies built for your exact application.

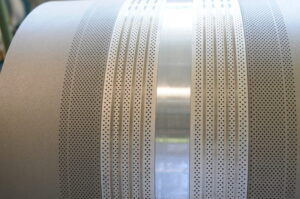

Tooling Materials & Cut Life

Choosing the right substrate is the first step toward predictable cut life. Below is a quick guide to each material we offer and when it delivers the greatest ROI.”

| Material | Typical Cut Life | Best For |

|---|---|---|

| Tungsten-Carbide | ≈ 100 M clean cuts | Ultra-hard alloy ideal for abrasive liners, composites and high-volume runs; routinely delivers 10–12× the cut life of conventional tool steels under normal operating conditions. |

| Powdered-Metal | ≈ 60 M clean cuts | Vacuum-sintered matrix that balances toughness with edge retention. |

| Tool Steel | ≈ 40 M clean cuts | For adjustable wedge applications, lower volume, lower wear resistance, higher toughness, lower budget. |

Cut-life values assume 60 µm PET liner at 200 fpm; mileage varies with substrate and tension settings.

Have a Die That Needs Checking?

Get a 360° performance evaluation, wear analysis, and bounce-detection report—fast.

From Reverse Engineering to Full Custom Design

ICD offers complete die lifecycle support, from initial consultation to rebuilds and redesigns. We capture ± 0.0005 in. CAD data and can prototype replacement geometry within 48 hours.

Our custom-engineered dies are built for:

- Max widths up to 50”

- Roll diameters up to 26”

- Overall die lengths up to 125”

- Support for ultrasonic, thermal, pressure, and elastic entrapment bonding

Our services include:

Industries We Serve

From medical-grade nonwovens to complex label shapes, ICD builds tooling solutions for high-performance converting environments:

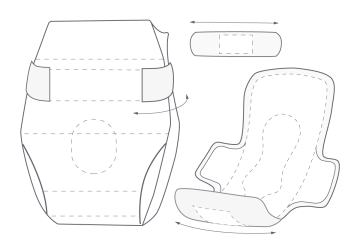

Nonwovens

Custom rotary dies for hygiene & filtration.

Labels

Precision slitting & kiss-cut tooling.

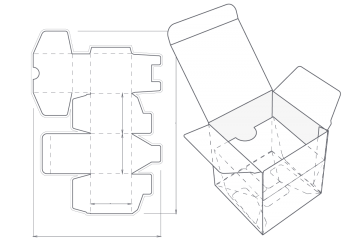

Packaging

High-speed flexible-packaging solutions

Medical Products

Burr-free cuts for medical tapes.

Price • Quality • Service

ICD was built on three promises: competitive pricing that respects your budget, ISO-level quality that protects your brand, and a service model designed to keep your converting line moving. Most orders ship in 7–10 days and every die leaves with a full QA dossier, calibration log and lifetime service history in Maxcess.

- Price — 50–65 % savings

Rebuilding costs a fraction of a new die, freeing budget for line upgrades or spare tooling. - Performance — ≈ 100 M or more cuts

Tungsten-carbide dies achieve long life between sharpenings and hold tolerances to ± 0.0005 in. - Service — 7–10 day turnaround

Global technicians rebuild on a rapid cycle and return a data-backed performance report.

Contact International Cutting Die

Ready to Design Your Next Advantage?

Let’s build a smarter die that lasts longer, runs cleaner, and adapts to your bonding or lamination processes.