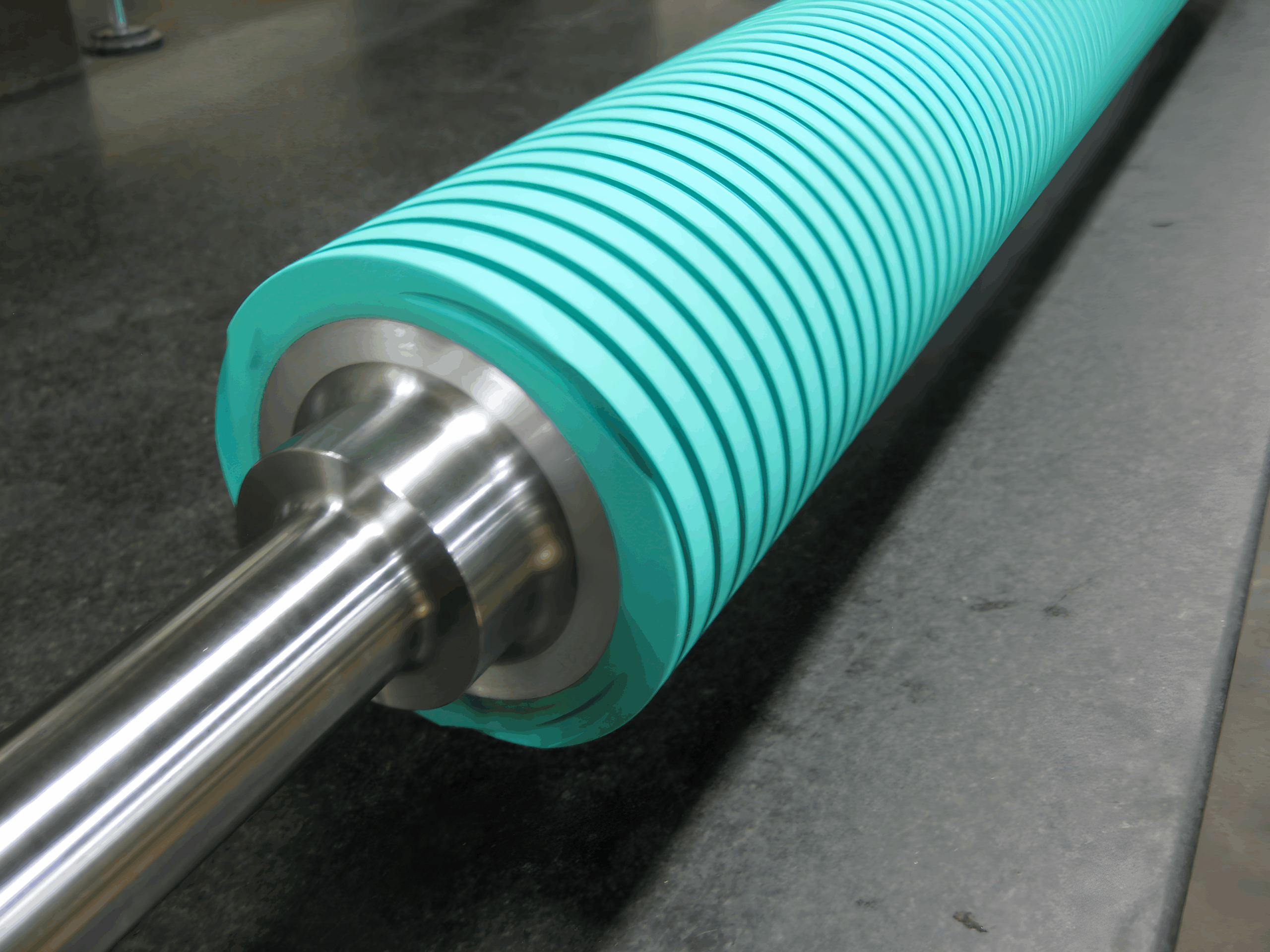

Valley Roller Grooved Rubber Roll Covers

Grooved Rubber Spreader Rolls are precision-engineered rubber-covered rolls designed to improve web control by eliminating wrinkles, removing air, enhancing traction, and improving tracking. Built to meet the demands of a wide range of industries, these rolls help optimize production lines with specialized grooving patterns for better performance and material handling.

Benefits of Grooved Rubber Spreader Rolls:

- Effectively removes wrinkles, air bubbles, and misalignments

- Improves web tension and tracking in high-speed applications

- Customizable groove patterns to suit specific web materials

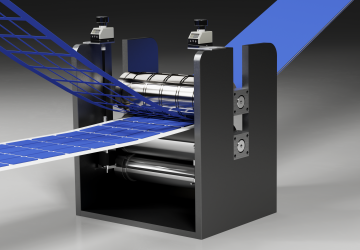

- Ideal for converting, printing, laminating, and more

Grooved Rubber Spreader Rolls for Advanced Web Handling

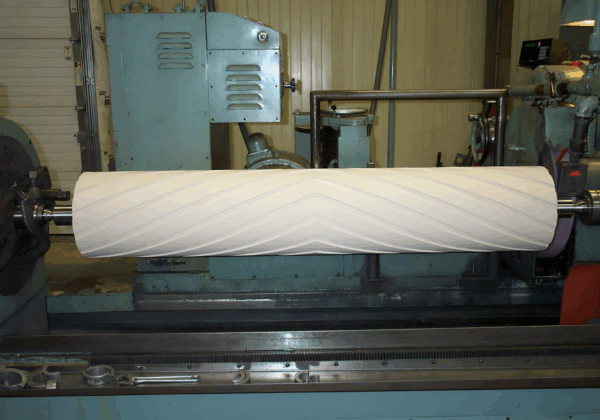

Purpose-Built for Web Performance

Grooved Rubber Spreader Rolls are designed to solve common web handling issues—like wrinkling, air entrapment, and slippage—by leveraging precision-machined surface grooves that actively influence how the web interacts with the roll. These engineered grooves help enhance material control while reducing scrap and improving output quality.

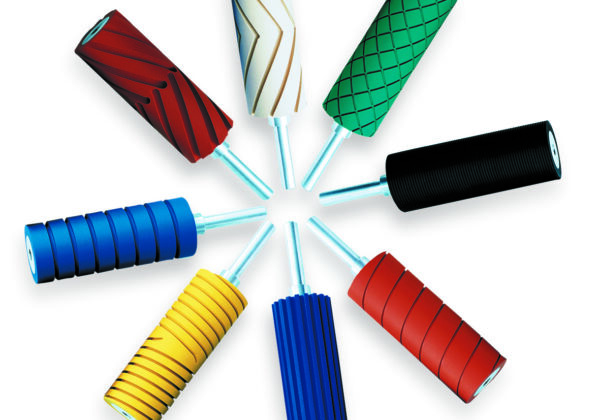

Custom Groove Patterns Available

With computerized grooving capabilities, choose from a wide range of precision groove patterns to address specific application needs, including:

- Spreading

- De-wrinkling

- Non-slip enhancement

- Air elimination

- Tracking improvement

- Circumferential or spiral grooves

- Herringbone, lateral fluted, and Vent-a-Nip configurations

Whether you’re working with film, paper, nonwovens, or laminates, the correct groove geometry can be customized to optimize web control.

Built for Compatibility

Grooved Rubber Spreader Rolls are available across a wide range of sizes and rubber compounds, ensuring compatibility and tailored for performance in converting, printing, packaging, and industrial processing lines.

Product Sheets

Featured Products

RotoAdjust Dual Adjustable Anvil

The new RotoAdjust offers state-of-the-art Industry 4.0 automation and data analytics to run better, faster, and smarter. Unlock tomorrow’s automation potential today.

AccuAdjust Dual Adjustable Anvil

AccuAdjust solves liner variability issues and allows easy cutting of PET, Glassine, Kraft and more with a simple turn of a precision digital dial. Cut perfect labels and minimize material consumption no matter the liner material.

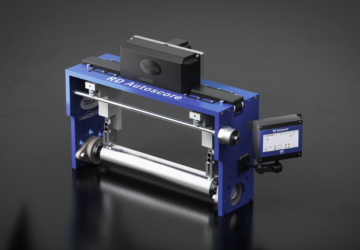

RD AutoScore

Keep operators safe and reduce setup time with the Tidland RD AutoScore system.

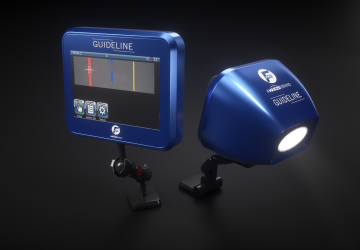

GuideLine & Guideline High Resolution (HR) Digital Line Guide Sensor Overview

Detect lines, edges of lines, graphic patterns, and more where traditional line sensors don’t work at a competitive price point. The GuideLine is suitable for the most demanding line guide applications.