Maxcess Opens First Rotary Die Manufacturing Facility in Huzhou, China

Maxcess Opens First RotoMetrics Rotary Die Manufacturing Facility in Huzhou, China Huzhou, February 16, 2022 – Maxcess, a global leader in innovative products and services for web handling applications, announced the opening of its new RotoMetrics, a Maxcess brand, rotary die-cutting factory in China. The new plant will manufacture and refurbish magnetic cylinders for flexible […]

Maxcess Launches the Tidland D6X Differential Air Shaft

With a wide range of torque outputs and easy maintenance at competitive pricing, customers will see less downtime Oak Brook, Illinois, January 27, 2022- Maxcess, a global leader in innovative products and services for web handling applications, today unveiled the Tidland D6X differential air shaft. Ideal for packaging and general converting applications, the D6X improves on […]

RotoMetrics Expands Flexible Die Production with New Plant

RotoMetrics Expands Flexible Die Production with New Plant RotoMetrics, A Maxcess Brand, opens a new state-of-the-art flexible die manufacturing facility in the St. Louis area to better serve its customers in the Americas Oak Brook, Illinois, November 11, 2021- Maxcess, a global leader in innovative solutions and services for web handling applications, announced a new state-of-the-art […]

Anodized Coatings

Anodized coatings extend roller life by improving wear resistance, corrosion protection, and surface performance. Whether you need Type II for cost-effective upgrades or Type III Hard Coat for extreme applications, Componex has a solution built for your web handling challenges.

- Improved abrasion resistance and durability

- Enhanced corrosion protection

- Available in Type II clear or black anodize; custom colors by request

- Available in Type III Natural or black

- Sealed with Nickel Fluoride Acetate or Teflon (PTFE)

Print Cylinders

RotoMetrics has an outstanding reputation for design, engineering, innovating best in class and industry leading products, and our print cylinders are no different

We manufacture all of our own printing solutions to exact OEM requirements in order to optimize accuracy, consistency and longevity of any flexographic print cylinders on the market

This now includes the addition of our own fully integrated anodizing line allowing us to ensure a consistently optimal surface protection coating that is stronger than the competition

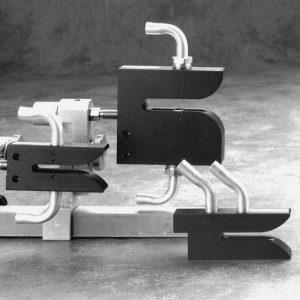

Pneumatic Sensors

The Fife pneumatic sensors serve as invaluable tools for a wide range of web applications, particularly those involving both opaque and clear films. Their non-corrosive body construction guarantees longevity and unwavering reliability, even in demanding operational conditions. These sensors are intrinsically safe, making them suitable for use in hazardous environments where combustible gases are present. They boast durability and resistance against clogs, ensuring a consistently efficient performance. The flexible mounting and positioning assemblies of these pneumatic sensors facilitate a swift and effortless installation process, further enhancing their utility in diverse industrial settings.