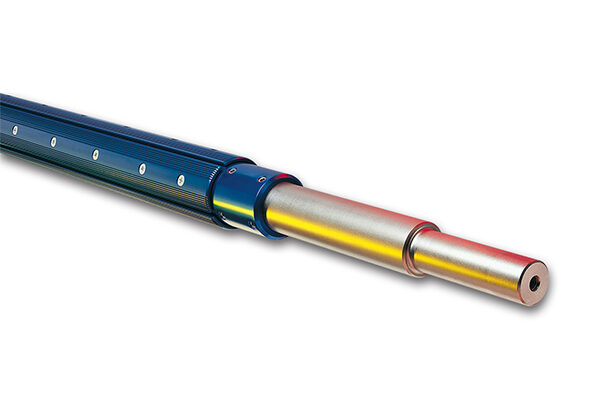

Leaf Shafts

Eliminates thin wall core deformation for superior roll quality and reduced vibration

360 degree radial and full length expansion for winding single or multiple rolls, with or without cores, improving product quality

Fixed leaf design provides improved roll centering and clearance for loading

Leaf Shafts Overview

Designed for a wide range of converting applications, these shafts are best for the elimination of thin wall core deformation. The 360º radial expanding grip along the entire leaf face delivers more winding surface and allows for the winding of single or multiple rolls, with or without cores.

With smooth, polished external leaves, these shafts are particularly suited for delicate materials. Leaf Shafts are built tough, with bodies constructed of standard steel, alloy steel or aluminum and internal tubes made of durable, hard-wearing rubber. Simple modular construction and standardized components mean quick off-the-shelf spares service and easy in-plant maintenance when necessary.

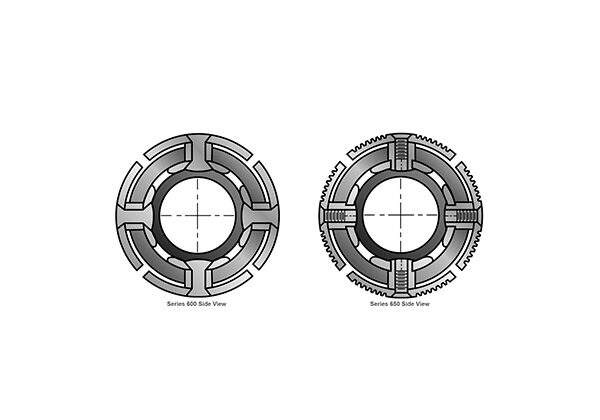

Series 650- designed for light to medium-duty 50.8 mm to 152.4 mm ID Cores

Series 750- designed for heavy-duty 177.8 mm to 609.6 mm ID cores

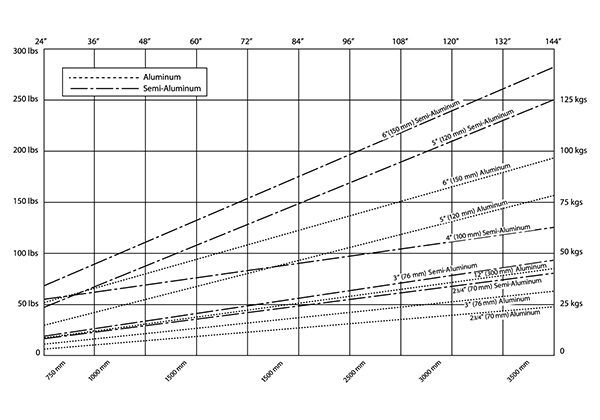

*Torque capacities per inch of web, shown at 80 psi

Leaf Shaft Series 650 (Light to Heavy Duty) - Fiber Core

| Torque for Nominal Size 2 in (50.8mm) | 46 in-lbs5.20 Nm |

|---|---|

| Torque for Nominal Size 2.75 in (69.85) | 88 in-lbs9.94 Nm |

| Torque for Nominal Size 3 in (76.2 mm) | 106 in-lbs11.98 Nm |

| Torque for Nominal Size 4 in (101.6 mm) | 212 in-lbs23.95 Nm |

| Torque for Nominal Size 5 in (127 mm) | 368 in-lbs41.58 |

| Torque for Nominal Size 6 in (152.4 mm) | 616 in-lbs69.60 Nm |

Leaf Shaft Series 650 (Light to Heavy Duty) - Steel Core

| Torque for Nominal Size 2 in (50.8mm) | 30 in-lbs3.39 Nm |

|---|---|

| Torque for Nominal Size 2.75 in (69.85) | 58 in-lbs6.55 Nm |

| Torque for Nominal Size 3 in (76.2 mm) | 70 in-lbs7.91 Nm |

| Torque for Nominal Size 4 in (101.6 mm) | 140 in-lbs15.82 Nm |

| Torque for Nominal Size 5 in (127 mm) | 243 in-lbs27.46 Nm |

| Torque for Nominal Size 6 in (152.4 mm) | 407 in-lbs45.99 Nm |

Leaf Shaft Series 750 (Light to Heavy Duty) - Fiber Core

| Torque for Nominal Size 8 in (203.2 mm) | 461 in-lbs52.09 Nm |

|---|---|

| Torque for Nominal Size 10 in (254 mm) | 671 in-lbs75.82 Nm |

| Torque for Nominal Size 12 in (304.8 mm) | 1,107 in-lbs125.08 Nm |

| Torque for Nominal Size 16 in (406.4 mm) | 1,476 in-lbs166.78 Nm |

| Torque for Nominal Size 24 in (609.6 mm) | 2,952 in-lbs333.56 Nm |

Leaf Shaft Series 750 (Light to Heavy Duty) - Steel Core

| Torque for Nominal Size 8 in (203.2 mm) | 304 in-lbs34.35 Nm |

|---|---|

| Torque for Nominal Size 10 in (254 mm) | 443 in-lbs50.06 Nm |

| Torque for Nominal Size 12 in (304.8 mm) | 731 in-lbs82.60 Nm |

| Torque for Nominal Size 16 in (406.4 mm) | 974 in-lbs110.06 Nm |

| Torque for Nominal Size 24 in (609.6 mm) | 1,948 in-lbs220.11 Nm |

- Tag and Label

- Packaging

- Cardboard

- Food and Beverage

- Flexible Packaging

- Pharmaceutical

- Nonwovens

- Battery

- Towel and Tissue

- Specialty Converting

Related Products

Kantiroller

This innovative steering guide delivers precise web or strip position by bending the web through a long entering span, providing immediate lateral correction for transient errors while also compensating for the web or strip steady-state errors.

Performance Series Knifeholder

Achieve faster setups, increased productivity and unrivaled finished roll quality with the Performance Series Knifeholder. Available in three sizes to accommodate a wide range of slitting materials and web speeds in a wide range of applications.

Great-Expansion Shaft

Tidland’s Great-Expansion Shaft is specifically designed for ID core variation changes, allowing for core diameter adjustments while it remains on the machine.

Foot Mounted Magnetic Particle Brakes

Transform your reliable, durable, foot-mounted MAGPOWR C Series Clutches into brakes with a locking bracket.

B Series Magnetic Particle Brakes

B Series Shaft Mounted Magnetic Particle Brakes give operators high-quality, dependable performance within a simple, durable device that’s easy to install.