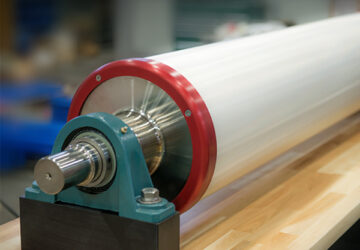

Lug Shafts

Lug-style design prevents roll slippage during fast startups and shutdowns

Available in many sizes to accommodate any converting application

Designed with wider lugs for longer shaft life in applications with high torque and/or heavy loads

Lug Shafts Overview

Strong and versatile, Tidland Lug Shafts deliver superior performance in the widest range of converting

applications. Unmatched in positive holding power, the lug-style design eliminates core damage, prevents roll slippage through fast startups and shutdowns and minimizes vibration at high web speeds. Simple modular construction and standardized components mean quick off-the-shelf spares service and easy in-plant maintenance when necessary.

Series 500- 50.8 mm to 152.4 mm ID cores

Series 550- 76.2 mm ID cores

*Torque capacities per inch of web, shown at 80 psi.

Lug Shafts Series 500 - Air (Light to Heavy Duty) - Fiber Core

| Torque for Nominal Size 2 in (50.8 mm) | 78 in-lbs8.81 Nm |

|---|---|

| Torque for Nominal Size 2 .75 in (69.85 mm) | 136 in-lbs15.37 Nm |

| Torque for Nominal Size 3 in (76.2 mm) | 175 in-lbs19.77 Nm |

| Torque for Nominal Size 4 in (101.6 mm) | 370 in-lbs41.81 Nm |

| Torque for Nominal Size 5 in (127 mm) | 564 in-lbs63.73 Nm |

| Torque for Nominal Size 6 in (152.4 mm) | 958 in-lbs108.25 Nm |

Lug Shafts Series 500 - Air (Light to Heavy Duty) - Steel Core

| Torque for Nominal Size 2 in (50.8 mm) | 31 in-lbs3.50 Nm |

|---|---|

| Torque for Nominal Size 2.75 in (69.85 mm) | 54 in-lbs6.10 Nm |

| Torque for Nominal Size 3 in (76.2 mm) | 70 in-lbs7.91 Nm |

| Torque for Nominal Size 4 in (101.6 mm) | 148 in-lbs16.72 Nm |

| Torque for Nominal Size 5 in (127 mm) | 226 in-lbs25.54 Nm |

| Torque for Nominal Size 6 in (152.4 mm) | 383 in-lbs43.28 Nm |

Lug Shafts Series 550 - Mechanical (Medium to Heavy Duty) - Fiber Core

| Torque for Nominal Size 3 in (76.2 mm) | 225 in-lbs25.42 Nm |

|---|---|

| Torque for Nominal Size 6 in (152.4 mm) | 450 in-lbs50.85 Nm |

Lug Shafts Series 550 - Mechanical (Medium to Heavy Duty) - Steel Core

| Torque for Nominal Size 3 in (76.2 mm) | 90 in-lbs10.17 Nm |

|---|---|

| Torque for Nominal Size 6 in (152.4 mm) | 180 in-lbs20.24 Nm |

Product Sheets

Installation Guide

- Tag and Label

- Packaging

- Cardboard

- Food and Beverage

- Flexible Packaging

- Pharmaceutical

- Nonwovens

- Battery

- Towel and Tissue

- Specialty Converting

Related Products

Cygnus Tension Controller

The Cygnus Tension Controller is an advanced, intuitive tension controller in a compact enclosure that's easy to navigate for operators.

D-MAX OI-TS Operator Interface

User-friendly touchscreen operator interface allowing for easy and intuitive control of web guiding systems in industrial applications.

Ultrashaft Carbon Fiber Air Shaft

Tidland’s Ultrashaft Carbon Fiber Air Shafts are customizable and offer the perfect combination of durability and high-speed operation in a lightweight, ergonomic air shaft.

Vacuum Tension Rolls

A uniquely engineered internal vacuum system provides a strong, stable grip on a variety of materials, ensuring consistent and reliable web handling.