Need assistance determining the correct roll diameter and shaft size? Use our WINertia Componex calculation tool.

Product Subcategories

All Precision Rolls Products

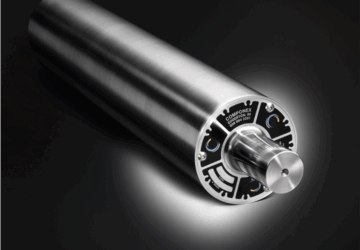

Componex Shaft Options

Componex Shaft options are engineered to optimize your dead-shaft idler performance. With a choice of solid, tubular, stainless, or aluminum designs, these shafts balance strength, weight savings, and corrosion resistance.

Componex WINertia™ Aluminum Live Shaft Idler

The Componex WINertia™ Aluminum Live Shaft Idler provides a simple, cost-effective solution for demanding web handling applications. Its unique design eliminates the need for complex customization and reduces manufacturing costs.

Componex End Cap Serial Customization

Every standard end cap clearly displays both the Componex job number and your customer part number, creating an easy reference to roll specifications and order information, simplifying identification and the reorder process.

Componex WINertia™ Self-Adjusting Bearings

Componex Patented WINertia Self-Adjusting Bearing System offers protection from some of the greatest challenges idlers have in web handling, misalignment, linear expansion, free spin, and relubrication. WINertia design innovations ensure long life and less downtime keeping your machines running at peak performance.

Plasma Coatings

Enhance performance of precision rollers with plasma coatings from Webex and Componex. Our proprietary coatings are available with a variety of materials engineered to resist wear, chemical attack, and adhesive buildup—making them ideal for demanding applications in converting, printing, laminating, and more. The product is safe for intended use, per applicable U.S. FDA contact regulations.

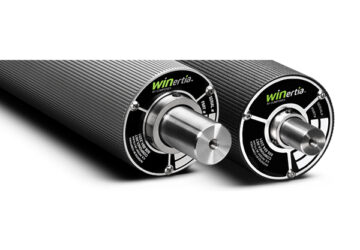

WEBEX FeatherLight™ Carbon Fiber Composite Dead Shaft Idler Rolls

FeatherLight™ Carbon Fiber Dead Shaft Idlers offer ultra-low inertia and high load capacity in a corrosion-resistant composite design. Ideal for high-speed, tension-sensitive applications, these idlers ensure smoother starts, tighter control, and reduced energy usage.

Valley Roller Grooved Rubber Roll Covers

Eliminate wrinkles, improve web tracking, and reduce air bubbles with precision-engineered Grooved Rubber Spreader Rolls.

WEBEX FeatherLight™ Carbon Fiber Composite Live Shaft Idler Rolls

FeatherLight™ Carbon Fiber Composite Live Shaft Idler Rolls offer ultra-low inertia and high load capacity in a lightweight carbon fiber design. Built for high-speed, demanding environments, they ensure smooth web handling and long-term durability—now available in standard or custom specs.

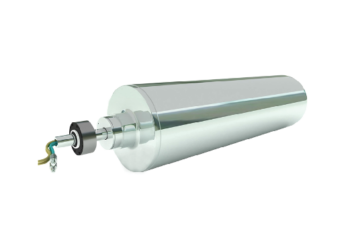

WEBEX Stainless Steel Live Shaft Idler Rolls

Tackle harsh environments with stainless steel live shaft idlers from WEBEX. Engineered to withstand corrosion, high heat, and chemical exposure, these precision rolls are ideal for demanding web handling applications in converting, laminating, printing, and more. Optional coatings and surface finishes enhance durability, wear resistance, and web control.

Mounts for Dead Shaft Idler Rolls

Mounts provide a stable, secure connection for idler rolls, ensuring consistent, reliable performance.

WINtrac™ Coatings

Engineered with advanced surface technology, WINtrac™ coatings provide improved traction and release on WINertia rollers without damaging sensitive webs, making them ideal for film, foil, paper, and other delicate substrates.

Anodized Coatings

By forming a hard aluminum oxide surface, anodized roller coatings provide a cost-effective way to extend the life of your idlers, protecting against scratching, wear, and abrasive materials that can shorten roller service life.

WINertia™ AV-Air Vent Aluminum Dead Shaft Idler

WINertia™ AV-Air Dead Shaft Idlers eliminate entrapped air 7.5x faster, ensuring wrinkle-free web handling, stable tension, and optimal performance for high-speed converting and printing lines.

Electric HTR Roller

Achieve process temperatures quickly with minimal downtime while maintaining an even heat profile. With the ability to reach temperatures up to 850°F in just 1 hour, multiple heating zones for even heat distribution, and seamless integration options, the Electric HTR Roller offers a rapid and reliable solution for your production needs.

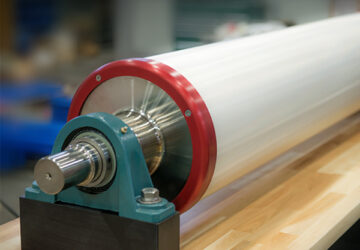

WEBEX Heat Transfer Rolls (Chill Rolls)

A uniquely engineered internal temperature management system allows for precise temperature control, ensuring consistent, reliable performance in heat transfer applications.

Vacuum Tension Rolls

A uniquely engineered internal vacuum system provides a strong, stable grip on a variety of materials, ensuring consistent and reliable web handling.