Plasma Coatings

Componex and Webex Plasma Coatings are available with various proprietary polymers offering excellent release with adhesives and inks, resistance to chemical attack, and wear and abrasion resistance. The product is safe for intended use, per applicable U.S. FDA contact regulations.

Benefits of Plasma Coatings:

- Excellent adhesive and ink release

- Wear and abrasion resistance

- Superior durability with release properties

- Eliminate air entrapment

Webex & Componex Plasma Coating Options

Maxcess is excited to announce our latest innovation: Componex and Webex Plasma Coatings. As a trusted leader in web handling, we proudly present a new line of coatings that uphold the quality associated with the Webex name. Our coatings provide the exceptional release and nonstick properties, as well as traction capabilities that you expect, all at competitive pricing and reasonable lead times.

Webex and Componex Plasma Coatings are engineered to enhance the performance and durability of precision rolls across a wide range of applications. These high-performance surface treatments improve wear resistance, provide exceptional chemical and thermal protection, and enable superior release in adhesive and ink-based processes. Whether operating in a printing, laminating, or flexible packaging environment, plasma coatings help extend roll life and reduce maintenance downtime.

Available options include:

- Non-stick coating options for excellent adhesive and ink release

- Eliminate air entrapment

- Textured coatings for enhanced traction in web handling applications

- Low friction

- Wear and abrasion resistance

- Resistance to chemical attack

- High-temperature coatings for use with heat transfer rolls & thermal processing, able to withstand temperatures up to 450

Compatible Products

Plasma coatings can be applied to a range of precision rolls including:

- Componex WINertia™ Idler Rolls

- Webex Heat Transfer Rolls

- Webex Vacuum Rolls

- Spreader & Speciality Rolls

See our Plasma Coatings FAQs for answers to common questions about durability, applications, and maintenance.

Plasma Coatings Comparison

-

PCW-410

One of our smoothest coatings within this series, offering traction, corrosion resistance, and superior wear and abrasion resistance.

- Best used for winder drums and applications that do not require release

- Traction coating only, no release

-

PCW-430

One of our smoothest coatings within this series offering traction, cut, as well as wear and abrasion resistance.

- Best used for winder drums and applications that do not require release, great for sensitive webs

- Traction coating only, no release

-

PCW-440

Any application where release is not a requirement, such as winder drums in paper mills.

- Offering high traction

- Cut and abrasion resistance

- Traction coating only, no release

-

PCW-460

A Plasma applied ceramic, excellent choice for corrosion and erosion resistance as well as resistance to harsh chemicals.

-

PCW-466

A Plasma applied ceramic, excellent choice for corrosion and abrasion resistance, and offers some impact resistance.

-

PCW-910

One of our smoothest coatings within this series, offering excellent traction, corrosion resistance, and wear and abrasion resistance.

-

PCW-930

One of our smoothest coatings within this series, offering excellent high release with water-based adhesives, traction, corrosion resistance, and superior wear and abrasion resistance.

-

PCW-940

More textured surface, offering high release with water-based adhesives.

- Good choice for winder drums in paper mills

- Splicing tape will not stick to the coating

-

PCW-960

A Plasma applied ceramic, excellent choice for release, additional traction, corrosion and erosion resistance as well as resistance to harsh chemicals.

-

PCW-1110

Improves coating life and performance, with high release from hot melt, solvent-based, and pressure-sensitive adhesives.

- Corrosion resistant

- Improves web tracking

-

PCW-1130

A hard, wear-resistant release coating from hot melt, solvent-based, and pressure-sensitive adhesives; A good choice for sensitive webs.

- The polymer gives it a softer profile so as not to damage the web

- Improved web tracking

-

PCW-1140

A hard, wear-resistant release coating with more texture to improve traction and web tracking. High release with hot melt, solvent-based, and pressure-sensitive adhesives. The polymer provides a softer profile, preventing it from marking the web, even on sensitive materials.

- Improves web tracking

-

PCW-1210

Improves coating life and performance resistance; a good general-purpose release coating.

- Corrosion resistant

- Improves web tracking

-

PCW-1230

Hardfaced release coating offers high release with adhesives, improving coating life and performance.

- Good general purpose release coating

- Improves web tracking

-

PCW-1240

Hardfaced release coating offers high release with adhesives and high traction, improving coating life and performance with high wear and abrasion resistance.

- Corrosion resistant

- Improves web tracking

Featured Products

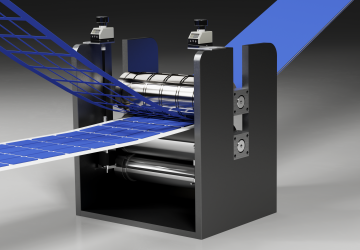

RotoAdjust Dual Adjustable Anvil

The new RotoAdjust offers state-of-the-art Industry 4.0 automation and data analytics to run better, faster, and smarter. Unlock tomorrow’s automation potential today.

AccuAdjust Dual Adjustable Anvil

AccuAdjust solves liner variability issues and allows easy cutting of PET, Glassine, Kraft and more with a simple turn of a precision digital dial. Cut perfect labels and minimize material consumption no matter the liner material.

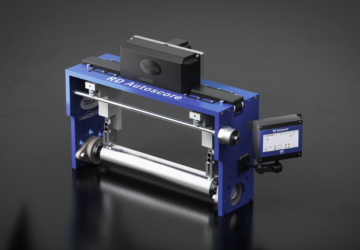

RD AutoScore

Keep operators safe and reduce setup time with the Tidland RD AutoScore system.

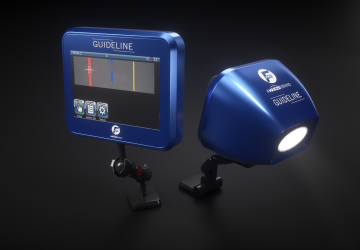

GuideLine & Guideline High Resolution (HR) Digital Line Guide Sensor Overview

Detect lines, edges of lines, graphic patterns, and more where traditional line sensors don’t work at a competitive price point. The GuideLine is suitable for the most demanding line guide applications.