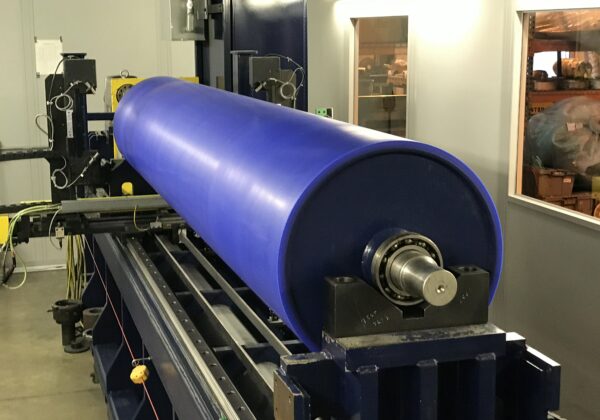

Valley Roller Rubber Covered Roll Solutions

Valley Roller’s rubber-covered rollers and nip rolls are engineered for optimal web handling, tracking, and tension control. With over 3,000 custom rubber compounds, we deliver precision-ground solutions tailored to your exact application.

Key Benefits:

- Over 3,000 rubber compounds tailored for traction, cushioning, or chemical resistance

- Ideal for nip rolls, spreader rolls, squeegees, applicators, and laminating systems

- CNC-controlled grinding, crowning, and grooving for high precision

- Fast-turnaround refurbishment services available from two regional facilities

- Laser-based inspections ensure ≤ 0.001” TIR and consistent surface finish

Engineered for Demanding Web Handling Applications

Valley Roller’s in-house team evaluates your current roller setup and recommends the ideal compound for performance, durability, and speed. Each cover is cured using large autoclaves and precision-ground to exacting tolerances using 14 different industrial roll grinders. We also provide full recoating and regrinding services to extend roller lifespan.

Precision Grinding & Surface Quality

Our computer-controlled temperature and pressure ramping systems ensure consistent physical properties across all rubber-covered rolls. Every finished roll is tested for grind profile, runout, and hardness — and for near-perfect TIR requirements, we offer laser-based non-contact inspections.

Common Applications

- Converting & laminating lines for films, foils, paper, and adhesives.

- Flexible packaging systems requiring cushioning, wrinkle control, or air elimination.

- Printing and graphics requiring consistent tension and transfer are critical.

- Industrial web tensioning with custom durometers and coatings.

- Food-safe and cleanroom environments using specialty rubber compounds.

Upgrade your production line with custom rubber-covered rollers from Valley Roller. Request a quote or speak to an application engineer today.

Product Sheets

- Battery

- Cardboard

- Flexible Packaging

- Food and Beverage

- Nonwovens

- Packaging

- Pharmaceutical

- Specialty Converting

- Tag and Label

- Towel and Tissue

Related Products

D-MAX Enhanced Web Guiding Controller

A compact and easy-to-use web guide controller that offers precise and reliable control for a variety of industrial applications.

Performance Series Knifeholder

Achieve faster setups, increased productivity and unrivaled finished roll quality with the Performance Series Knifeholder. Available in three sizes to accommodate a wide range of slitting materials and web speeds in a wide range of applications.

WEBEX Heat Transfer Rolls (Chill Rolls)

A uniquely engineered internal temperature management system allows for precise temperature control, ensuring consistent, reliable performance in heat transfer applications.

Webex Idler Rolls

We offer more than 400 standard configurations and numerous customizable options available for coating, plating, finish, groove patterns, shaft style, and environmental capabilities.