Tidland Reel Spools

The Tidland Series 860 Reel Spool Shaft is engineered specifically to excel in demanding mill environments. By using this air shaft instead of multiple reel spool mandrels, you can save thousands in production costs and save time with the easy-to-change, two-piece expanding elements.

Reel Spools by Tidland

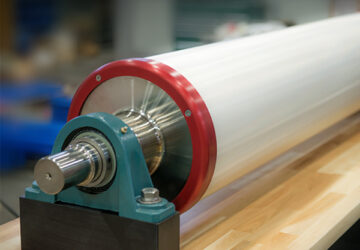

The Series 860 is a heavy-duty air shaft designed for maximum reliability and performance in demanding mill environments, reducing the cost and storage of expensive reel spool mandrels. This reel spool shaft utilizes our innovative two-piece expanding elements, with a spiral design that provides 360º of radial grip and intrinsically equalized load distribution.

The advanced features of these reel spool shafts include a two-piece expanding element design, nonmetallic retraction springs, durable poly bladder and a fail-safe multi-circuit air system, with check valves to ensure that a loss of air in one element will not affect the expansion and performance of the other elements. Its ergonomic design also provides increased safety by eliminating the need for dangerous locking collars or wrenches.

Key Features of the Tidland Series 860 Reel Spool Shaft

- Heavy-duty shaft engineered to specifically perform in demanding mill environments

- Spiral strip design for 360° of radial grip and equalized load distribution

- Easy-to-change two-piece expanding elements

- Customizable journal detail to fit existing equipment

- Various sizes available to accommodate any mill application

- Maximized productivity with faster, easier shaft handling

- Durable construction designed to withstand abuse and abrasion

- Manufactured to your specifications

- Reduce cost and storage of expensive reel spool mandrels

Tidland Winding Accessories

Tidland offers a complete line of accessories to keep your Series 860 Reel Spool Shaft running at peak efficiency. These accessories include:

- Air Inflation Tools

- Recoiling Air Hose

- Air Hose with Fittings

- Air Release Tool

- Hole Punch and Locator Gauge

- Journal Puller Assembly

- Mill Wedge

- Chuck Interconnect Hose

- Quick Disconnect Hose

- Quick Disconnect Fitting

- Mark I Roll Saver, Adapters, and Sledge Weight

- Mark II Roll Saver

- Drive Coupling & Universal Joint Assemblies

Tidland Reel Spools - Torque Capacities per Nominal Core Size

| Nominal Core Size | 10.00 in254 mm |

|---|---|

| Fiber Core | 885 lb-in885 lb-in |

| Steel Core | 938 lb-in938 lb-in |

| Nominal Core Size | 12.00 in304.8 mm |

| Fiber Core | 1,415 lb-in1,415 lb-in |

| Steel Core | 1,500 lb-in1,500 lb-in |

| Nominal Core Size | 14.00 in355.6 mm |

| Fiber Core | 1,650 lb-in1,650 lb-in |

| Steel Core | 1,749 lb-in1,749 lb-in |

| Nominal Core Size | 20.00 in508 mm |

| Fiber Core | 2,944 lb-in2,944 lb-in |

| Steel Core | 3,120 lb-in3,120 lb-in |

- Tag and Label

- Packaging

- Cardboard

- Food and Beverage

- Flexible Packaging

- Pharmaceutical

- Nonwovens

- Battery

- Towel and Tissue

- Specialty Converting

Related Products

D-MAX OI-TS Operator Interface

User-friendly touchscreen operator interface allowing for easy and intuitive control of web guiding systems in industrial applications.

ESP Electronic Slitter Positioning System

Save downtime and increase productivity with Tidland’s ESP Electronic Slitter Positioning System. This highly-accurate, automated solution is ideal in mill finishing and other large-scale converting operations, providing reliability in the most demanding environments.

GTS Load Cells

MAGPOWR’s GTS Global Load Cell ensures stability and accuracy, allowing tension to be precisely measured and controlled on a roll.

Vacuum Tension Rolls

A uniquely engineered internal vacuum system provides a strong, stable grip on a variety of materials, ensuring consistent and reliable web handling.