Technologies We Use for Die Quality Assurance

ICD applies precision measurement tools and patented detection systems to verify that every die meets exacting specifications before and after installation.

Precision Tolerance Verification

Measures die dimensions to ±0.0005 in., ensuring cuts meet critical specifications before deployment.

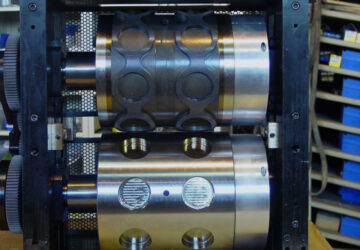

Laser-Driven Bounce Detection

Identifies die–anvil separation in under 0.25 seconds to confirm stability and avoid cut-depth variability.

Run-Out & Profile Measurement

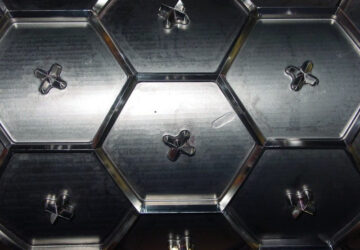

Uses advanced metrology tools to verify uniform geometry, ensuring consistent performance across the die profile.

Our Quality Assurance Protocols

Quality doesn’t end at manufacturing. Our QA program ensures every die we produce or service meets the strictest criteria for performance and reliability.

We verify OD, ID, and critical dimensions to ± 0.0005 in. and recalibrate the die–anvil gap before shipment.

We capture microscopic edge-profile images and hardness readings (HRC/Ra) to verify cutting efficiency. A PDF report with before/after photos is delivered for your ISO or customer files.

We capture microscopic edge-profile images and hardness readings (HRC/Ra) to verify cutting efficiency. A PDF report with before/after photos is delivered for your ISO or customer files.

Dynamic run-out testing (< 0.001 in.) plus 360° profile heat-map pinpoints high-spot wear before vibration can degrade cut quality in-line.

Certifications & Industry Standards

Trust the Maxcess team to ensure your die meets the spec, whether you’re operating under corporate QA mandates or third-party compliance protocols. With ICD onboard, we now support expanded compliance for high-speed converting operations and bonding techniques, including ultrasonic, thermal, and pressure bonding processes used in sensitive product lines. We design, manufacture, and inspect dies to meet key industry and regulatory standards, including:

- ISO 9001 Quality Management – audited process control

- FDA Material Compliance* – audited hygiene controls ensure contact-safe converting for medical, food & pharma packaging

- Customer-Specific Tolerance Requirements – medical & aerospace

- Industry Clean-Room Standards – nonwoven & semiconductor

*Material certificates supplied with each shipment.

Post-Installation Validation

In addition to testing in-house, we validate performance where it matters most: in your production environment.

Our service team can conduct real-world performance testing to confirm that the die function aligns with expectations in your unique line conditions. ICD’s patented AntiBounce and Bounce Detection technologies are assessed during field testing to help identify and prevent catastrophic die separation events in high-output lines.

Need a quick inspection first? Request a Die Evaluation →

We gather run data and operator feedback to generate post-installation reports detailing cut quality, wear trends, and recommendations. These reports now include ICD-informed benchmarks for wear resistance, particularly for long-run carbide dies rated for over 100 million cycles before sharpening.

If calibration or minor design adjustments are required after installation, we provide on-site or remote support to optimize performance and achieve peak efficiency. ICD specialists can be engaged to fine-tune bonding configurations or die alignment when working with nonwoven substrates or hygiene applications.

Support Across All Industries

Anywhere precision is mission-critical, our quality assurance team has your back. And now, with ICD’s sector-specific expertise in hygiene, filtration, and elastic entrapment dies, we bring deeper compliance knowledge to some of the most quality-critical applications on the market. Our QA services support converting operations in a wide range of sectors, including:

- Packaging

- Tag & Label

- Non-Woven Materials

- Medical Products

- Towel & Tissue

- Tire & Rubber

- Paper

- Battery / Specialty

Additional ICD Services Section

Enhance your quality assurance program with complementary services that address performance, longevity, and design optimization.

Die Rebuilding & Repair

Restore precision and extend die life with expert rebuilding and patented anti-bounce upgrades.

Die Product Evaluation

Comprehensive assessment to detect wear, misalignment, and performance issues before they cause downtime.

Custom Rotary Die Design

Engineer dies tailored to your materials, tolerances, and production speeds from the start.

Contact International Cutting Die

Ready to Validate Die Performance?

Book an ISO-compliant audit or on-press validation—report delivered in 48 hours.