Boschert Safety Chucks

Pre-engineered solution for roll support and torque transfer in unwind and rewind applications.

Contains a self-closing handwheel, in case manual closing is overlooked, to prevent unintentional shaft release – keeping your operators safe.

Available in an automated configuration to further improve safety and reduce setup time by remote activation away from pinch points.

Boschert Safety Chucks Overview

The Tidland Boschert Safety Chucks are a pre-engineered solution for roll support and torque transfer in unwind and rewind applications. With a variety of options to choose from, depending upon the level of safety and automation required, these versatile chucks deliver reduced setup times, improved roll quality, and lower maintenance costs.

Manual Safety Chucks are available in fixed or sliding designs, with a unique self-closing feature to ensure safe performance even if the operator neglects to close the chuck after loading. An effective load bearing design ensures long life and smooth rotation. Optional replaceable socket inserts and adapters for MAGPOWR global brakes make these chucks suitable for virtually any application.

A Laser Alignment Tool is available for purchase or rent to troubleshoot vibration or wear issues with safety chucks with VT inserts where misalignment may be the cause. See the Installation and Operation document below for more information.

*Sliding chuck axial adjustment is between 50.8 mm – 101.6 mm depending on model.

Boschert Safety Chucks - 22-30

| Shaft Length | 4.50 in114.3 mm |

|---|---|

| Maximum Roll Weight per Pair | 1,764 lb800 kg |

| Journal Square | 22 - 30 mm22 - 30 mm |

| Torque | 180 Nm180 Nm |

| Speed | 1,350 rpm1,350 rpm |

| Brake Model | 200, 205, 305T200, 205, 305T |

Boschert Safety Chucks - 30-40

| Shaft Length | 4.50 in114.3 mm |

|---|---|

| Maximum Roll Weight per Pair | 1,600 kg1,600 kg |

| Journal Square | 30 - 40 mm30 - 40 mm |

| Torque | 350 Nm350 Nm |

| Speed | 1,350 rpm1,350 rpm |

| Brake Model | 250, 305T, 380250, 305T, 380 |

Boschert Safety Chucks - 40-50

| Shaft Length | 4.50 in114.3 mm |

|---|---|

| Maximum Roll Weight per Pair | 2,800 kg2,800 kg |

| Journal Square | 40 - 50 mm40 - 50 mm |

| Torque | 1,100 Nm1,100 Nm |

| Speed | 1,350 rpm1,350 rpm |

| Brake Model | 305T, 460305T, 460 |

Installation Guide

User Manuals

Product Sheets

- Battery

- Cardboard

- Flexible Packaging

- Food and Beverage

- Nonwovens

- Packaging

- Pharmaceutical

- Specialty Converting

- Tag and Label

- Towel and Tissue

Related Products

D-MAX Enhanced Web Guiding Controller

A compact and easy-to-use web guide controller that offers precise and reliable control for a variety of industrial applications.

External Element Air Shafts

Our External Element Shafts feature innovative two-piece expanding elements for an impressive combination of balance and torque, as well as self-retraction, durable poly bladder, and a fail-safe multi-circuit air system.

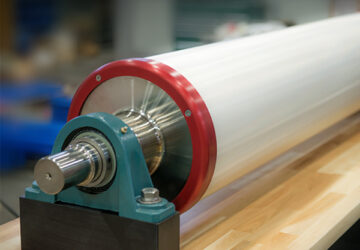

Vacuum Tension Rolls

A uniquely engineered internal vacuum system provides a strong, stable grip on a variety of materials, ensuring consistent and reliable web handling.

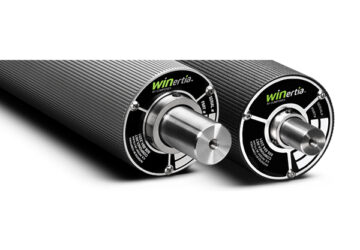

WINertia™ AV-Air Vent Aluminum Dead Shaft Idler

WINertia™ AV-Air Dead Shaft Idlers eliminate entrapped air 7.5x faster, ensuring wrinkle-free web handling, stable tension, and optimal performance for high-speed converting and printing lines.