Automate. Automate. Automate. One word that we, as manufacturers, hear constantly.

But, what does it really mean, especially in terms of web handling solutions? And what are the benefits of automation beyond just saving time and money?

We’ll go into how your company will, in fact, save time and money, but also reduce errors, increase quality, easily comply with safety requirements and exponentially increase your factory’s production output.

The Pros of Automation

The time to automate is now. Well, in actuality, the time to automate has been the last 3 decades.

However, the cost of installation, maintenance and training employees on the operation of new technology can easily feel out of reach for a lot of manufacturing companies, but the long-term benefits of automation far exceed these fears.

If your company has yet to make the jump into automation or is ready to partially or completely cut the cord with manual labor, let’s go over what your company has to gain from the benefits of automation for your web handling processes.

Increases Profitability and Production

Humans need breaks. Humans need sleep. Humans have personal lives. Arguably the biggest benefit of automation is that machines don’t need any of those things.

Automated systems continue to produce constantly, 24/7 and unattended, positively affecting your Time to Market, ultimately leading to increased productivity and larger profits for your company.

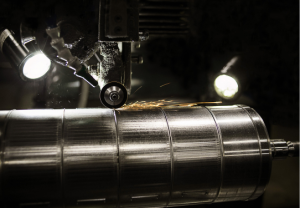

Dr. Dilwyn P. Jones, co-author of the Web Handling Handbook discusses how automating the web handling process drastically reduces the time it takes to make manual adjustments to machinery, providing consistent results, “coupled with machine software, [servo drives] can automate the machine setup, for example moving rewind arms and knives in order to change the cut pattern on a large slitter rewinder. This can be completed in seconds, compared with maybe an hour of manual repositioning. This gives an increase in productivity and less risk of error. Similarly, flying splices and roll changes can be carried out automatically, more quickly, while maintaining product quality.”

Reduces Dependency on Labor

Over the past several years, Maxcess International has seen an increase in demand for web handling automation. Automation efforts designed to reduce the dependence on labor has forever changed the industrial market as we know it, and it is even more important now.

With the increasing cost of an average worker, the scramble to reduce the bloated cost of labor is a constant for manufacturers. It goes without saying, automation eliminates historically manual tasks done by human workers. By embracing the convenience of automation, you’ll drastically reduce your dependency on labor, along with associated costs.

Not to mention, the shortage of new web operators is creating unique challenges in documenting internal web handling processes. So much so, that for the first time in web handling process history, an official handbook has been released as a resource for newcomers to become experts quicker and assist in further innovation of automation machinery. Automation greatly simplifies training for new operators and employees while encouraging hiring of new innovative and forward-thinking employees.

Ensures Quality Control and Consistent Results

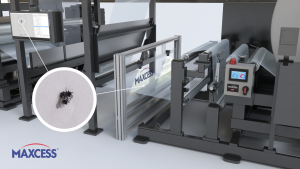

Machines designed to continuously run product inspections, either on or off the line, will produce more consistent work than their human counterparts. When you cut out the human variability that comes with quality control processes, you’ll produce higher quality, more consistent products while reducing waste caused by QC errors.

Smart vision inspection systems such as VisionMax 100% Inspection Systems continuously examine the material to mark or stop a line in order to remove defective product, ensuring quality output.

Supports Environmental and Worker Safety Efforts

We all want to create safe environments for our workers. Workplace safety should be everyone’s top priority. There’s no arguing that the COVID-19 pandemic has changed the way we conduct business. In the web handling world, companies were forced to drastically change their operations to accommodate new health regulations.

The demand for automated operations increased as manufacturers dealt with the challenge of maintaining output and productivity goals while navigating this uncertain labor landscape. Implementing automation for previously hazardous or complex tasks results in a safer work environment for all. VisionConnect Automation is just one of the ways to work smarter by automating workflows such as roll tracking and and slitter control.

Additionally, automatic sensors that monitor energy usage and provide precision acceleration or deceleration control can drastically reduce your energy costs

Reduces Lead Time and Downtime

Lead time and downtime are constant races against the clock. When you automate certain parts or all of your web handling processes, the result is reduced lead times overall.

Additionally, most, if not all, automated web handling equipment alerts you when it’s time for maintenance, like our product PressureMax. No more production lines coming to a screeching halt because someone forgot to plan ahead for maintenance.

Maximizes Competitiveness

It’s all about who can do it faster while maintaining the same quality. Benefits of automation include a decrease in cycle times and cost-per-piece while improving quality. Because you remove the chance for human error and variability, your output is faster, your quality increases— giving you an edge over your competitors.

A Manufacturing Tomorrow survey showed that 73% of manufacturers believe that automation is a business-critical move, while Forrester, in their Predictions 2022 Blog, bluntly stated that companies that automate will not only beat but obliterate, their competitors.

Web Handling Automation with Maxcess International

Automation is here to stay. With over 3 decades of automation use cases out there, we’ve seen the significant benefits of automation for every part of the manufacturing process, including web handling. When it comes to your web handling processes, we’re the experts in automating for every industry.

If you’re interested in exploring automation or working with Maxcess for easy integration and expert servicing, let’s schedule a consultation.